In the high-stakes world of industrial machinery, downtime is the enemy. A single leak in a hydraulic cylinder or a blown gasket in a chemical pump can halt production lines, damage environmental ecosystems, and cost thousands in repairs. While the seal is often the least expensive component in a system, it is arguably the most critical—making seal failure prevention a primary concern for engineers, OEMs, and maintenance teams across all industries.

At QZSEALS, we look beyond the rubber ring. We view sealing as a science of barrier integrity, where effective seal failure prevention depends on the correct interaction between design, material selection, and operating conditions. As a global expert in sealing design and manufacturing, we help OEMs and service professionals understand not just what a seal is, but how it survives, performs, and resists failure in dynamic industrial environments.

From the freezing depths of cryogenic applications to the scorching heat of steel mills, sealing systems are constantly exposed to pressure fluctuations, thermal cycling, chemical attack, and mechanical wear. Our mission is to deliver Flexible Sealing Solutions engineered specifically for long-term reliability and proactive seal failure prevention, even under extreme operating conditions.

This advanced guide moves beyond basic definitions and product catalogs. It is structured to support practical seal failure prevention strategies, combining failure analysis with real-world engineering solutions. We will examine why seals fail in hydraulic, pneumatic, and rotary systems, how to prevent extrusion under high pressure, and how to select the precise types of seals that maximize service life, reduce unplanned downtime, and improve overall system performance.

Part 1: Seal Failure Prevention — Understanding Root Causes

To choose the right product, engineers must first understand the forces at play. Most seal replacement tasks are due to four primary failure modes: Extrusion, Heat Hardening, Chemical Attack, and Wear.

1. Extrusion and Pressure Spikes

When system pressure is too high for the material, the seal is forced into the clearance gap between the metal hardware. This is called extrusion.

- The Solution: Use seals with integrated back-up rings or robust profiles. The SPGW Piston Seal is engineered for this exact scenario. Its multi-piece design includes hard anti-extrusion rings that protect the main sealing element during pressure spikes.

- Rod Protection: For rod applications facing pressure shock, the GSJ Seal Step Seal uses a high-modulus PTFE face that resists deforming under load.

2. Heat Hardening and Compression Set

Excessive heat causes elastomers to cross-link, becoming hard and brittle. They lose their “memory” (compression set) and fail to bounce back, causing leaks.

- The Solution: Switch to high-temperature materials like FKM or PTFE. For extreme heat where polymers melt, Metal Sealing Rings such as the Hollow Metal O-Ring are the only viable option.

3. Chemical Attack

Incompatible fluids cause seals to swell or dissolve.

- The Solution: For chemical processing, standard rubber is insufficient. The FEP Encapsulated O-Ring offers the chemical inertness of Teflon with the elasticity of a rubber core.

Part 2: Optimizing Hydraulic Cylinders

Hydraulic cylinders are the workhorses of industry. Hydraulic seals must manage fluid power efficiency while preventing environmental leakage.

Piston Sealing Strategies

The piston seal must prevent fluid bypass (drift). The choice depends on the duty cycle.

For Heavy Duty Load Holding:

Construction equipment requires zero drift. The SPG Piston Seal and the robust SPGW are industry standards. They provide a tight static seal.

For Low Friction/High Speed:

In servo-hydraulics or robotics, friction causes “stick-slip” (jerky motion). Here, the GSF Piston Seal Glyd Ring is superior. The PTFE face slides smoothly, reducing heat and wear.

For Balanced Performance (Low Friction + Reliable Sealing):

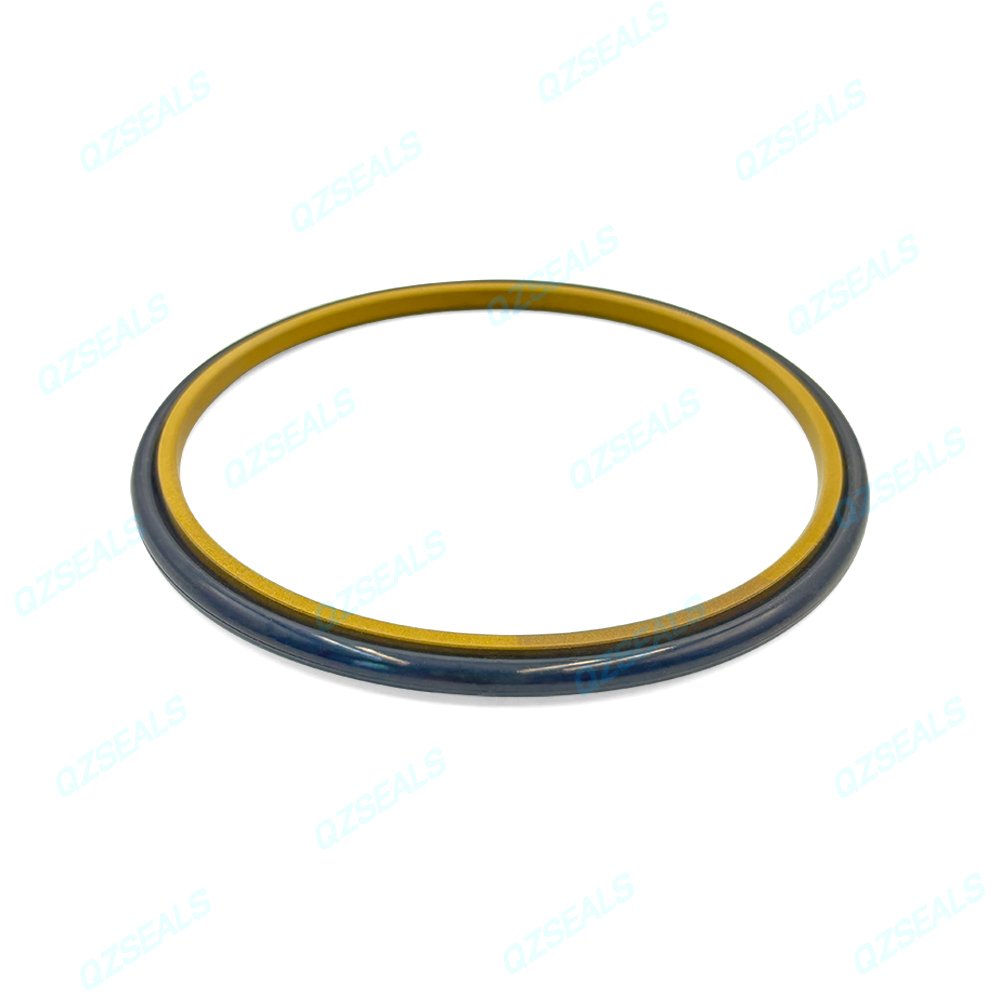

The PS08 piston seal is designed for applications requiring a combination of low friction and stable sealing performance. Its PTFE sealing ring, energized by an elastomer O-ring (e.g. NBR or BR40), ensures effective sealing over a wide pressure range while maintaining smooth piston movement. The PS08 is widely used in mobile hydraulics, machine tools, and injection molding equipment where efficiency, precision, and service life are critical.

For Double-Acting Systems:

When pressure comes from both sides, the KR Piston Seal is a compact, integrated solution that handles bi-directional pressure efficiently.

Rod Sealing: The Zero-Leak Standard

Leakage on the rod is unacceptable. It indicates a failure of the primary barrier.

- U-Cup Versatility: The IDI Rod Seal and UNS Piston Rod Seal use system pressure to energize the lips. The higher the pressure, the tighter they seal.

- Compact Retrofitting: For cylinders with limited gland space, the S8 Rod Seal and its variant, the One Way Compact Seal S8, provide full performance in a reduced profile.

Contamination Control

75% of hydraulic failures are caused by fluid contamination. Wiper seals are critical to system health.

- The GPTA Wiper Seal prevents dust ingress while preserving the oil film.

- For open-groove housings, the metal-cased PDR Wiper Seal ensures the wiper stays in place even under heavy mud accumulation.

Part 3: Managing Rotary Motion

Oil seals on rotating shafts face a different set of physics: frictional heat generation at the seal lip. A standard crank seal in an engine or a transmission seal in a gearbox must balance sealing force with lubrication.

The Industry Standard: TC Seals

The TC Oil Seal is the most common solution. It features a rubber lip, a metal case for stiffness, and a spring. However, for non-standard shafts, QZSEALS creates the Custom L2M Oil Seal to fit any dimension.

High-Speed and Chemical Rotary Solutions

When RPMs increase, rubber burns. QZSEALS utilizes PTFE for these conditions. The PTFE Oil Seal with Stainless Steel housing can run dry and resist aggressive acids that would destroy NBR seals.

Axial Protection

To protect the main seal from external splash and dust, we employ V-Rings. The VA Ring, VS Ring, and VL Ring rotate with the shaft, flinging contaminants away via centrifugal force.

Part 4: Static Sealing Mastery

Not all seals move. Static seals, like the O-ring and gasket, are vital for flanges and covers.

O-Rings: Beyond Basic Rubber

While we supply standard O-Ring Rubber Seals, complex applications need more.

- Size Flexibility: For massive flanges where molded rings are too expensive, O-Ring Cords are the answer. We supply PTFE Cord for chemical lines.

- Gasket Sealing: For flat surfaces, the Seal for Gasket applications varies. We offer Oil Resistant Asbestos Gaskets for steam and oil pipes, and Red Steel Paper Gaskets for economical sealing in automotive gearboxes.

- High Purity: In pharma and food, the PTFE Gasket ensures zero contamination.

Part 5: Advanced Engineering for Extreme Conditions

When standard engineering fails, QZSEALS turns to advanced physics.

Spring Energized Seals: Overcoming Thermal Cycling

In cryogenics (Liquid Nitrogen) or high-heat cycling, seal materials shrink or expand, causing leaks. A spring energized seal uses a metal spring to maintain constant pressure on the sealing lips, regardless of the polymer’s condition.

We manufacture specific spring profiles for specific loads:

- Helical Spring: Maximum load for static vacuum sealing.

- Meander Spring (V-Spring): Moderate load for reciprocating dynamic motion.

- Stainless Steel 301 Helicoil Springs: The standard for corrosion resistance.

These are widely used in dispensing machines and medical equipment.

Pneumatic Specialization

Air is compressible and lacks the lubricity of oil. The Z8 Pneumatic Seal uses a unique lip geometry to retain grease and maintain a seal at low pressures. For end-of-stroke damping, Buffer Seals (COP) prevent metal impact.

Part 6: Material Science and Customization

In industrial sealing applications, material selection and performance requirements are often governed by internationally recognized standards, such as ISO material testing standards.

Composite Wear Rings

To support the weight of a piston without scoring the bore, we use Wear Rings. The Phenolic Resin with Fabric Wear Ring is a composite material that absorbs side loads and embeds abrasive particles, protecting the cylinder.

PTFE and Bronze

Pure PTFE is slick but soft. By adding bronze powder, we create PTFE Filled Bronze Guide Tape. This material has high compressive strength and excellent thermal conductivity, dissipating heat away from the seal.

Bespoke Engineering

Off-the-shelf is not always enough. QZSEALS excels in Customized Rubber Products. We design Custom Inflatable Seals for complex door geometries and Fabric Reinforced Rubber Diaphragms for precision pumps.

Part 7: Industry Applications and Accessories

Our solutions extend into specialized industrial niches.

- Compressors: The PEEK Valve Plate withstands millions of cycles without fatigue.

- Fluid Handling: For aggressive slurries, High Pressure Graphite Gland Packing and Aramid Fiber Gland Packing provide robust sealing for pump shafts.

- Check Valves: High-precision PET Balls ensure reliable flow control in food and beverage systems.

- Gear Pumps: The Gear Pump Seal features a specialized figure-8 design to seal the pump housing efficiently.

Conclusion

Reliability is a choice. It comes from selecting the right design, the right material, and the right partner. Whether you are dealing with a leaking door weather seal or designing a subsea hydraulic actuator, the principles remain the same: contain the pressure, exclude the environment.

QZSEALS provides the expertise and the product range to ensure your success. From Rod Seals to Wiper Seals, and from standard O-Rings to custom engineered solutions, we are your global sealing partner.

Don’t let seal failure compromise your operations. Explore the QZSEALS catalog today and discover the difference that quality engineering makes.