How is rubber vulcanized?

Rubber vulcanization is the essential chemical process that transforms weak, sticky raw rubber into a durable, elastic, and high-performance material used in O-rings, oil seals, gaskets, and industrial sealing components. Without proper vulcanization, rubber would not withstand heat, pressure, chemicals, or long-term compression, making the process the foundation of modern sealing technology.Introduction — Why Vulcanization Matters in the Sealing Industry.

Rubber is the foundation of modern sealing technology—whether used in O-rings, oil seals, gaskets, hydraulic seals, or custom-molded parts. But raw, unprocessed rubber is weak, sticky, and melts easily under heat. It cannot handle pressure, chemicals, or mechanical stress. Learn more about global rubber standards from ASTM Rubber Standards.

To transform rubber into a durable, elastic, high-performance sealing material, manufacturers rely on a process called vulcanization.

This article explains how rubber is vulcanized, the chemical science behind the transformation, how different curing systems are chosen for sealing applications, and why vulcanization is the backbone of the entire rubber seal manufacturing process.

What Is Vulcanization?

Vulcanization is a chemical process that converts raw rubber—whether natural rubber (NR) or synthetic elastomers—into a strong, stable, and elastic material by forming cross-links between polymer chains.

Before vulcanization, raw rubber is:

soft

sticky

thermoplastic (melts when heated)

weak tensile strength

cannot maintain shape

After vulcanization, rubber becomes:

strong and durable

elastic but dimensionally stable

heat and compression resistant

chemically resistant

suitable for sealing under pressure

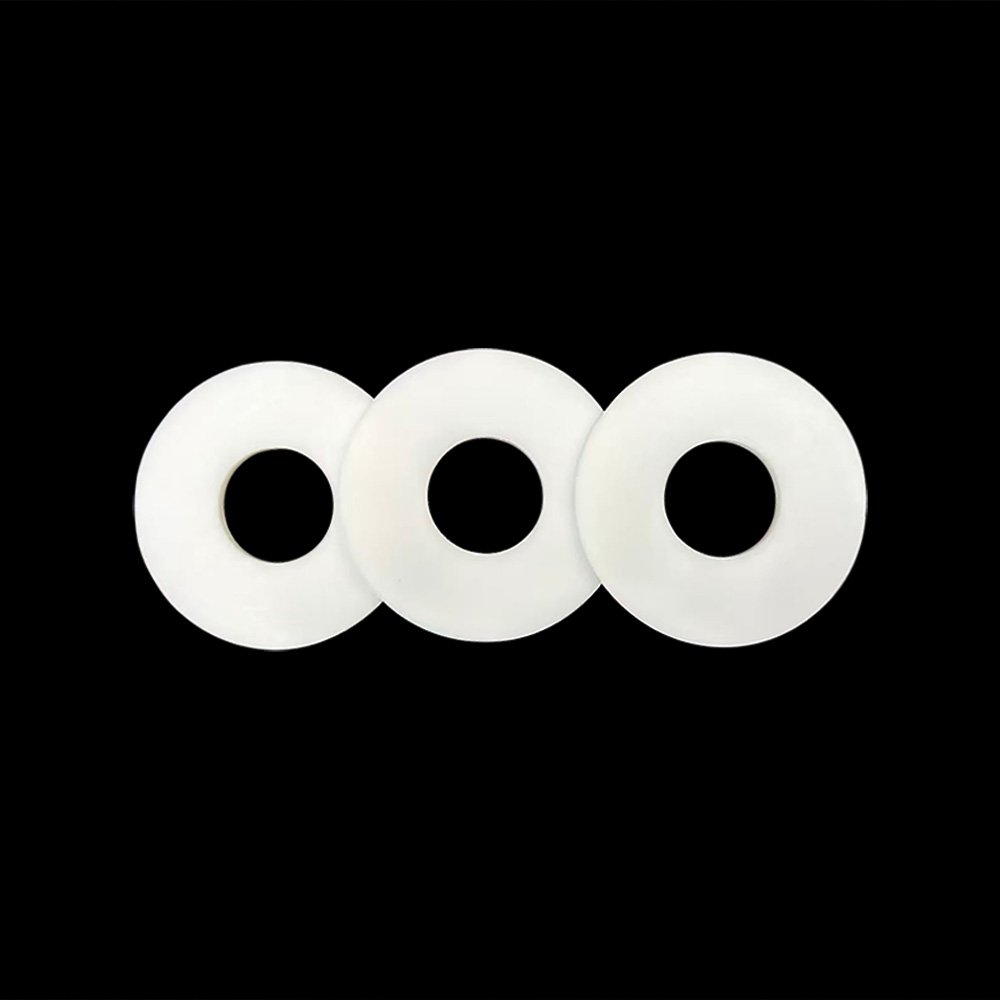

In the sealing industry, vulcanized rubber is used to produce:

O-rings (NBR, EPDM, FKM, HNBR, etc.)

U-cups, hydraulic seals

gaskets, molded parts

rubber-to-metal bonded seals

Without vulcanization, modern sealing technology simply would not exist.

The Science Behind Vulcanization

Understanding how rubber is vulcanized requires a look at polymer chemistry.

Stage 1 — Rubber’s Molecular Structure

Natural rubber is made of polyisoprene, long chains with carbon double bonds (C=C).

Many synthetic elastomers contain similar reactive sites.

These double bonds are the “anchor points” where curing chemistry occurs.

Stage 2 — Cross-linking

During vulcanization, a curing agent (traditionally sulfur) forms bridges between individual polymer chains.

This cross-linking creates:

a three-dimensional network

improved elasticity

high tensile & tear strength

compression-set resistance

dimensional stability

The difference can be visualized like cooked vs. uncooked spaghetti:

Uncooked spaghetti = raw polymer chains (easy to pull apart).

Cooked and dried spaghetti = cross-linked network (hard to separate).

Stage 3 — Thermoset Stability

Once cross-linking occurs, rubber becomes a thermoset material—it will not melt again, even under high temperatures.

This stability is essential for applications like:

hydraulic sealing

automotive engines

chemical processing

high-pressure pumps

rotating shaft sealing

How Is Rubber Vulcanized? (Step-by-Step Industrial Process)

This is the core question: how is rubber vulcanized?

Below is the sealing-industry workflow.

1. Raw Material Preparation

Rubber compounds are created by mixing:

base elastomer (NBR, EPDM, FKM, etc.)

vulcanizing agent (sulfur/peroxide/etc.)

accelerators (MBTS, TBBS, TMTD)

activators (ZnO, stearic acid)

fillers (carbon black, silica)

antioxidants

plasticizers or process oils

This mixture determines final O-ring or seal properties.

2. Molding or Extrusion

Before cross-linking occurs, rubber must be shaped into parts such as:

O-rings (compression molding / injection molding)

extrusion (cord stock, tubes, profiles)

The rubber is soft at this stage and can be easily formed.

3. Heating: The Actual Vulcanization

The shaped rubber is heated under controlled conditions.

Key curing parameters:

Temperature: typically 150–200°C

Pressure: depends on mold design

Time: from seconds to minutes (or longer for thick parts)

During heating, the curing system activates, and cross-linking begins.

4. Cooling & Post-Processing

After curing:

parts cool down

flash is removed

post-curing may be done (especially for FKM, silicone, peroxide-cured compounds)

This completes the transformation into fully vulcanized rubber seals.

Types of Vulcanization (Sulfur, Peroxide, and More)

Different sealing applications require different curing systems.

1. Sulfur Vulcanization (Most Common)

Used for:

NR, SBR

NBR

EPDM

HNBR (special systems)

Benefits:

excellent elasticity

high tensile strength

cost-effective

widely used for O-rings & seals

Drawback:

Not suitable for high-temperature applications over ~150–170°C.

2. Peroxide Vulcanization

Used for:

EPDM

silicone rubber

FKM in special formulations

Benefits:

excellent heat resistance

excellent compression set

chemical resistance

suitable for automotive, industrial and high-temperature sealing

Drawback:

Higher cost.

3. Special Curing Methods

Metal oxide curing (for CR)

Radiation vulcanization (EB curing)

Microwave vulcanization (continuous extrusion curing)

Urethane cross-linking systems

These are used in specialized sealing applications.

Industrial Equipment Used to Vulcanize Rubber

Compression molding vulcanizers

Used to produce O-rings, gaskets, molded seals.

Injection molding machines

High efficiency for mass-production of sealing components.

Vulcanizing autoclaves / steam curing tanks

Used for hose, tubing, and continuous profiles.

Microwave vulcanization lines

Used for extruded rubber strips, cords, and sponge rubber.

How Vulcanization Affects Seal Performance

1. Tensile Strength

Prevents tearing during installation.

2. Elasticity

Enables the O-ring to maintain sealing force.

3. Compression Set Resistance

Critical for long-term sealing.

4. Heat & Chemical Stability

Determines material selection (NBR vs. EPDM vs. FKM).

5. Abrasion Resistance

Important for dynamic seals.

Without proper vulcanization, sealing products would:

crack

deform

lose sealing force

fail under pressure

Common Applications of Vulcanized Rubber in the Sealing Industry

O-rings (static & dynamic sealing)

oil seals

hydraulic & pneumatic seals

gaskets

rubber-to-metal bonded seals

extruded cord O-rings (endless rings)

Vulcanization ensures these components maintain structural integrity in:

automotive engines

excavators and agricultural machinery

hydraulic pumps

chemical processing plants

pipeline equipment

compressors and valves

Frequently Asked Questions

Q1: How is rubber vulcanized in O-ring splicing?

Cord stock ends are coated with adhesive, joined, and vulcanized in a heated mold to form endless rings.

Q2: Is vulcanized rubber environmentally friendly?

Vulcanized rubber is durable and can be:

recycled into crumb rubber

reprocessed as filler

used in construction materials

Conclusion — Vulcanization Enables Modern Sealing Technology

The question “How is rubber vulcanized?” is central to understanding how industrial sealing products are made.

Vulcanization:

transforms weak raw rubber into strong industrial materials

gives O-rings and seals the durability needed for extreme environments

allows modern machinery, automobiles, pumps, and reactors to operate safely

For the sealing industry, vulcanization is not just a chemical reaction—it is the foundation that makes precision sealing possible.