Hydraulic systems are widely used in industrial machinery, mobile equipment, construction machines, and manufacturing plants. Their efficiency and reliability depend heavily on the ability to control pressurized fluids while preventing leakage and contamination. At the heart of this process are hydraulic gaskets and seals, small but critical components that ensure safe operation, pressure retention, and long-term system performance.

At QZSEALS, we specialize in the design and production of hydraulic gaskets and sealing solutions for a wide range of operating conditions. This guide provides an in-depth overview of the main types of hydraulic gaskets and seals, their functions, and how they contribute to the overall integrity of hydraulic systems.

The Role of Hydraulic Gaskets in Modern Hydraulic Systems

Hydraulic gaskets are designed to seal interfaces within hydraulic systems, preventing fluid leakage while maintaining pressure and protecting internal components. These seals must perform under demanding conditions, including high pressure, fluctuating temperatures, continuous motion, and exposure to aggressive hydraulic fluids.

A well-designed hydraulic sealing system helps to:

Prevent internal and external leakage

Maintain consistent system pressure

Reduce friction and wear

Protect components from contamination

Extend service life and reduce maintenance costs

Different sealing elements are used depending on whether the application involves dynamic movement or static connections, as well as the pressure level and environmental conditions.

Rod Seals: Reliable Dynamic Sealing Along the Rod

Rod seals are one of the most critical sealing components in hydraulic cylinders. They are installed in the cylinder head and prevent pressurized hydraulic fluid from leaking out along the piston rod during extension and retraction.

Function and Importance

The primary role of a rod seal is to maintain a tight dynamic seal between the moving rod and the stationary cylinder housing. Without an effective rod seal, fluid leakage can occur, resulting in pressure loss, reduced efficiency, and potential safety hazards.

Performance Requirements

Rod seals must withstand:

High system pressures

Repeated sliding motion

Abrasive wear

Chemical exposure to hydraulic oils

They also need to maintain elasticity and sealing force over long operating periods.

QZSEALS Rod Seal Solutions

At QZSEALS, rod seals are manufactured using advanced elastomers, polyurethane, and PTFE-based compounds. Our designs focus on low friction, high wear resistance, and excellent extrusion resistance, ensuring reliable performance even in heavy-duty hydraulic applications.

Piston Seals: Maintaining Pressure and System Efficiency

Piston seals are installed on the piston inside a hydraulic cylinder and serve to separate pressure chambers. Their main function is to prevent fluid from passing across the piston, allowing the hydraulic system to generate force efficiently.

Key Functions

Maintain pressure on both sides of the piston

Enable smooth linear movement

Reduce internal leakage

Improve energy efficiency

Operating Conditions

Piston seals often operate under higher pressure loads than rod seals and must accommodate bidirectional sealing. They also experience continuous friction during operation, making material selection crucial.

QZSEALS Piston Seals

QZSEALS piston seals are designed to provide stable sealing under high pressure and temperature variations. Our products use optimized sealing profiles and high-performance materials to minimize friction while maximizing sealing reliability.

Guide Rings (Wear Rings): Ensuring Alignment and Stability

Guide rings, also known as wear rings, play a supporting role in hydraulic systems. Although they do not directly seal fluid, they are essential for protecting seals and maintaining precise alignment.

Purpose of Guide Rings

Absorb side loads

Prevent metal-to-metal contact

Maintain correct piston and rod alignment

Extend the service life of seals

Without guide rings, seals would be exposed to uneven loads, increasing wear and the risk of premature failure.

Materials and Design

Guide rings are commonly manufactured from reinforced PTFE, phenolic resin, or high-strength polymers.

QZSEALS Guide Rings

QZSEALS guide rings are engineered to provide excellent wear resistance and dimensional stability, ensuring smooth operation and long-term system reliability even in high-load applications.

Wipers (Scrapers): First Line of Defense Against Contamination

Wipers, also called scrapers, are installed at the outermost position of the cylinder head. Their role is to remove contaminants from the rod surface before they enter the hydraulic system.

Why Wipers Are Essential

Contaminants such as dust, dirt, sand, moisture, and chemicals can severely damage internal seals and components. Wipers prevent these particles from being dragged into the system during rod retraction.

Performance Characteristics

Effective scraping action

Resistance to environmental exposure

Compatibility with rod surface finishes

QZSEALS Wiper Solutions

QZSEALS offers a range of wipers with optimized lip designs to ensure reliable contaminant removal while minimizing friction and wear on the rod surface.

Static Seals: Reliable Sealing for Fixed Connections

Static seals are used in areas where there is no relative movement between components, such as flanges, end caps, covers, and valve housings. Many hydraulic components are designed in accordance with ISO standards for hydraulic systems to ensure safety, reliability, and compatibility.

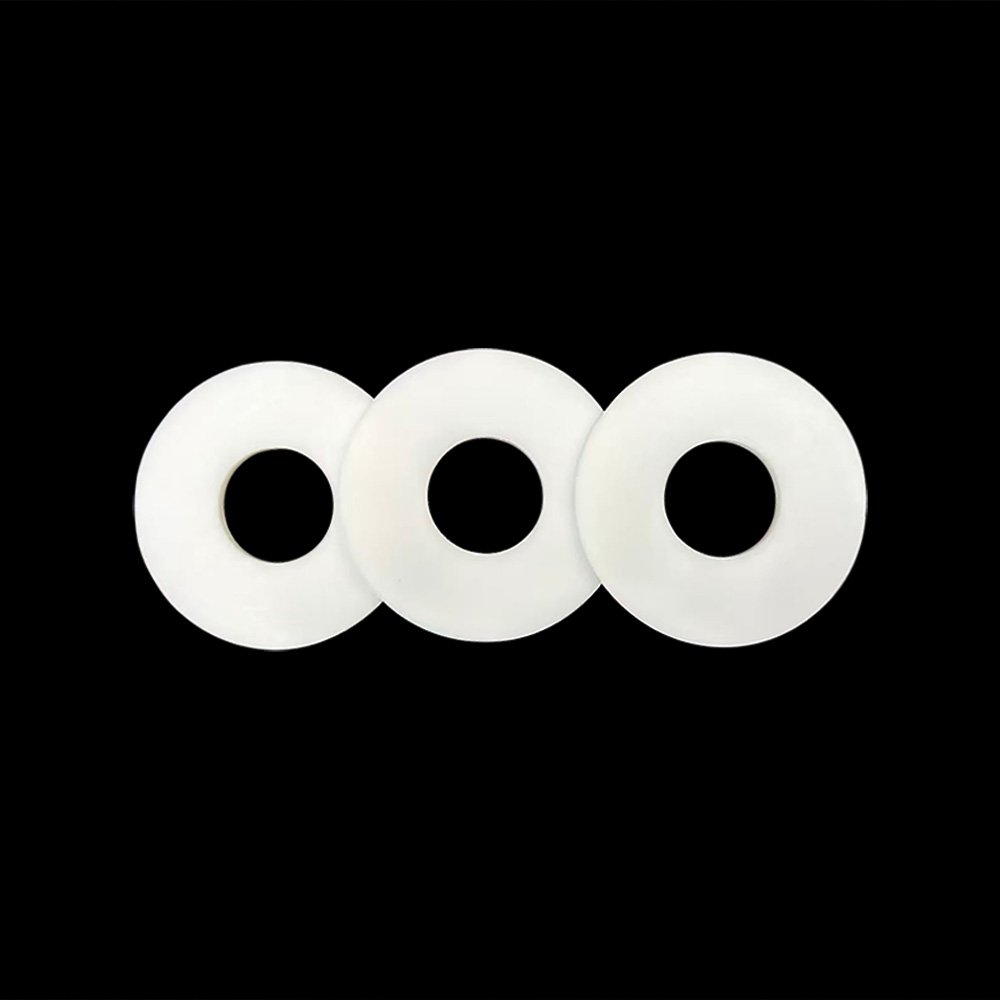

Common Types of Static Seals

Application Requirements

Static seals must resist:

System pressure

Temperature variations

Chemical attack from hydraulic fluids

QZSEALS Static Sealing Solutions

QZSEALS provides static seals in NBR, FKM, EPDM, PTFE, and other materials to meet a wide range of industrial requirements.

Cartridge Valve Seals: Precision and Safety in Hydraulic Control

Cartridge valves are widely used in modern hydraulic manifolds for flow control, pressure regulation, and directional control. The seals used in these valves are critical to system safety and performance.

Functions of Cartridge Valve Seals

Prevent internal and external leakage

Ensure accurate pressure control

Allow quick installation and replacement

QZSEALS Valve Sealing Components

Our cartridge valve seals are designed for high precision and reliability, supporting stable hydraulic performance in demanding industrial environments.

Material Selection for Hydraulic Gaskets

Choosing the right material is essential for sealing performance. Common materials include:

NBR: Good oil resistance and cost-effective

FKM (Viton®): High temperature and chemical resistance

PU: Excellent wear resistance

PTFE: Low friction and chemical inertness

QZSEALS assists customers in selecting the most suitable materials based on operating conditions and application requirements.

Why Quality Hydraulic Gaskets Matter

High-quality hydraulic gaskets reduce downtime, prevent fluid loss, and improve overall system efficiency. Poor sealing solutions can lead to leaks, contamination, increased maintenance, and costly equipment failures.

By investing in reliable sealing components, manufacturers and operators can significantly improve productivity and operational safety.

QZSEALS – Your Trusted Partner for Hydraulic Sealing Solutions

QZSEALS specializes in the production of hydraulic gaskets and seals for industrial and mobile applications. We supply standard and custom sealing solutions designed to meet real-world operating conditions.

Our strengths include:

Consistent product quality

Custom design and sealing material selection

Competitive pricing

Technical support and fast response

If you are looking for dependable hydraulic sealing solutions or customized gaskets, contact QZSEALS today. Our experienced team is ready to support your project from design to delivery.