Introduction: The Silent Sentinel of Modern Machinery

Deep within the heart of every engine, pump, and actuator, a silent sentinel stands guard. This component, often no larger than a coin, is the industrial seal. Its job is relentless: to contain immense pressures, exclude harmful contaminants, and ensure the seamless operation of the world’s most critical machinery. While the question “what is a seal?” can be answered simply—it’s a device that prevents leakage—this definition barely scratches the surface of its importance. The true meaning of an industrial seal is one of reliability, safety, and efficiency.

To truly appreciate these components, we must look beyond their static form and consider their entire journey. A seal has a lifecycle, a path that begins long before it is installed and ends long after it has served its purpose. This guide will walk you through the complete lifecycle of an industrial seal, from its conceptual design to its eventual replacement. Understanding this journey, including proper seal selection and seal application, is key for engineers, maintenance professionals, and designers who rely on these parts to keep our world running. As a global partner in sealing technology, QZSEALS is involved at every stage, providing the technical expertise and high-quality products necessary for success in demanding industries like aerospace, energy, and automotive.

Stage 1: Conception – Defining the Sealing Challenge

Every industrial seal begins not as a physical object, but as a problem to be solved. A design engineer might ask, “What is this seal for?” The answer defines its entire existence. Is it meant to contain hydraulic fluid in a high-pressure cylinder? Or perhaps it needs to protect sensitive bearings from fine dust in a mining operation. This initial stage is about defining the exact requirements of the job.

To do this systematically, engineers often use a framework to analyze the operating environment. A common and effective method considers the following key parameters:

- Size: What are the precise physical dimensions required? This includes the inside diameter, outside diameter, and cross-sectional thickness of the seal and its housing. Accuracy is paramount.

- Temperature: What are the minimum and maximum temperatures the industrial seal will experience? This includes both the ambient temperature and any heat generated by the system’s operation. Temperature extremes are a primary factor in material selection.

- Application: Is the application static or dynamic? If dynamic, does it involve reciprocating, rotating, or oscillating motion? Correct seal application depends on understanding this fully.

- Media: What substances will the industrial seal come into contact with? This could be hydraulic oil, corrosive chemicals, steam, or food products. The seal’s material must be chemically compatible with the media to prevent degradation.

- Pressure: What level of pressure must the industrial seal contain? Will it be subjected to a constant high pressure, a vacuum, or sudden pressure spikes? High pressure can force a seal out of its groove, a failure known as extrusion.

- Speed: In dynamic applications, how fast will the parts move? High speed affects seal selection and longevity.

At QZSEALS, our technical consultation process begins here. By helping our partners accurately define these conditions, we ensure the journey starts on the right path, leading to a sealing solution that is both effective and reliable.

Stage 2: Creation – The Science of Material Selection and Design

Once the challenge is defined, the process of creation begins. This stage involves two critical, intertwined decisions: choosing the right material and engineering the correct physical form. The success of the industrial seal depends entirely on getting both of these right.

Choosing the Right Material: The Foundation of Performance

The material is the heart of the industrial seal. It dictates its resistance to heat, chemicals, and physical wear. There are several major families of materials used in modern sealing, each with unique properties. You can explore a variety of these in our Sealing Material section.

- Elastomers (Rubber): This is the most common category, known for flexibility and resilience. A typical rubber seal is made from compounds like Nitrile (NBR), which is excellent for oils, or FKM (Viton®), which offers superior heat and chemical resistance. Each elastomer offers a different balance of properties.

- Fluoropolymers (PTFE): Famous for its near-universal chemical inertness and extremely low friction, PTFE is a problem-solver in aggressive environments. It is not elastic like rubber, so it is often used in designs like Spring Energized Seals or Gaskets.

- Engineering Plastics: Materials like PEEK and PET offer high mechanical strength, rigidity, and temperature resistance. They are often used for structural components within a sealing system, such as backup rings or the durable Valve Plates found in air compressors.

- Metals: For the most extreme conditions of temperature, pressure, or radiation, only Metal Seals will suffice. Alloys like stainless steel or Inconel® are formed into precise rings, such as Hollow Metal O-Rings, for applications in nuclear power and aerospace.

Engineering the Perfect Form: A Look at Seal Types

With a material chosen, the engineer must select a design—the industrial seal’s physical shape. The geometry of the seal is optimized for its specific task. Here are some of the most common industrial seal types:

- O-Rings: The simple, versatile torus shape makes the O-Ring the most widely used seal in the world for both static and dynamic applications. For added chemical resistance, Encapsulated O-Rings provide a protective PTFE jacket over a flexible core. For large, non-standard static seals, O-Ring Cord can be cut to length and bonded to form a custom ring.

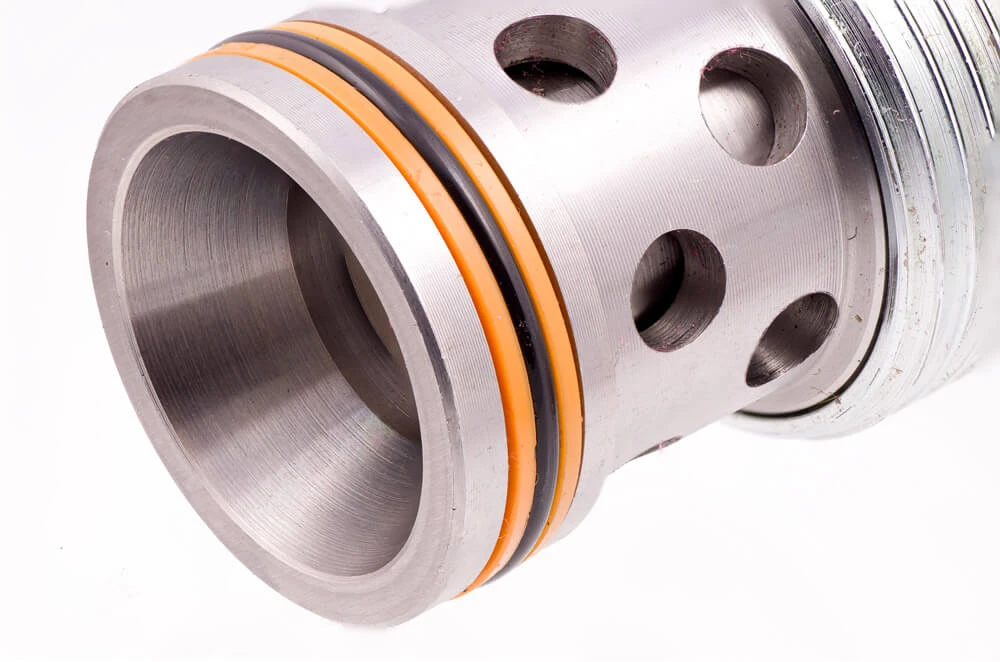

- Hydraulic Seals: This is a broad category of specialized seals designed for fluid power systems. They work together as a system:

- Piston Seals (like the SPG Piston Seal) prevent fluid from bypassing the piston head, ensuring efficient force generation.

- Rod Seals prevent fluid from leaking out of the cylinder along the moving rod.

- Wiper Seals are the first line of defense, scraping contaminants off the rod before they can enter the system.

- Wear Rings and Guide Strips support and guide the moving parts to prevent metal-to-metal contact and protect the seals.

- Oil Seals: Also known as rotary shaft seals, these are essential for sealing rotating components. A typical TC Oil Seal contains lubricants in gearboxes and protects bearings. A crankshaft seal in an engine is a perfect example of a critical oil seal application.

- Mechanical Seals: These are more complex sealing devices used in pumps and mixers. They consist of multiple components, including rotating and stationary faces, that create a seal capable of handling high pressures and speeds. Our Gear Pump Seals are an example of seals designed for these demanding rotary applications.

Stage 3: Application – Installation and Integration

A perfectly designed and manufactured industrial seal can still fail if it is not installed correctly. Proper seal application ensures a long service life.

The Importance of Correct Installation

Attention to detail during installation can prevent the vast majority of premature seal failures. Key best practices include:

- Cleanliness is Critical: The seal groove and all surrounding hardware must be perfectly clean and free of debris, old sealant, and rust.

- Check for Damage: Inspect the hardware for any sharp edges, burrs, or nicks that could cut or damage the new seal during installation. These should be smoothed out before proceeding.

- Use Lubrication: A light coating of a compatible lubricant on the seal and its mating surfaces helps it slide into place without twisting or tearing.

- Use the Right Tools: Avoid using sharp tools like screwdrivers that can easily damage the seal. Use specialized, non-marring installation tools when possible.

- Avoid Twisting: Ensure that seals, especially O-rings, are not twisted in their grooves. A twisted seal will not seat correctly and will inevitably leak.

The Difference Between a Seal and a Sealant

This is also a good time to clarify a common point of confusion. What is the difference between a mechanical seal and a product like a gasket sealer or consumer products like Flex Seal?

- A Mechanical Seal (like a gasket, O-ring, or oil seal) is a pre-formed, engineered component. It seals by being compressed between two surfaces, using its physical shape and material properties to block the leak path.

- A Sealant (like a gasket sealer or RTV silicone) is a chemical product. It is applied as a liquid or paste and cures in place to form a solid, adhesive barrier. It is often used to supplement a traditional gasket or, in some cases, to create a “formed-in-place” gasket.

QZSEALS specializes in the design and manufacturing of high-performance mechanical industrial seal, which is the primary sealing solution in most industrial and OEM applications.

Stage 4: Operation – The Industrial Seal at Work

Once installed, the seal begins its intended service life. During this stage, it is subjected to the full force of the operating conditions defined in Stage 1. The seal is in a constant battle against pressure, heat, chemicals, and mechanical movement. The seal’s design and material work together to ensure it wins this battle for thousands of hours or millions of cycles.

For example, inside a hydraulic pump, the Pump Seal must withstand continuous rotation and high-pressure fluid. In a chemical processing plant, a Diaphragm might be flexing continuously to isolate a pressure gauge from a corrosive fluid, faithfully transmitting pressure without allowing contamination. A black seal made of EPDM on a car’s door weather seal endures constant compression, temperature swings, and exposure to UV radiation to keep out wind and rain. Every moment of operation is a test of the industrial seal’s engineering.

Stage 5: Evaluation and Replacement – The End of the Journey

No seal lasts forever. Over time, all materials will age and wear. The final stage of a seal’s lifecycle is its evaluation and, ultimately, its replacement. Being able to recognize the signs of a failing seal is a crucial skill for any maintenance professional.

Recognizing the Signs of Seal Failure

A failing seal will almost always provide warning signs. Catching these early can prevent costly secondary damage to the equipment. Common signs include:

- Visible Leakage: This is the most obvious and common symptom. Any fluid or gas escaping from a sealed joint is a clear indicator of failure.

- Contamination: If the fluid in a system (e.g., hydraulic oil) appears milky, foamy, or dirty, it may indicate that an external seal has failed, allowing moisture or dirt to enter.

- Reduced Performance: In a hydraulic or pneumatic system, a loss of speed, power, or pressure can be caused by an internal seal that is leaking and allowing fluid to bypass.

- Increased Temperature: A failing dynamic seal can create excess friction, leading to a noticeable increase in the operating temperature around the sealed area.

- Physical Degradation: Upon inspection, a failed seal may appear hardened, cracked, brittle, or “chewed up” from extrusion. It might also be swollen or feel soft and mushy from a chemical attack.

The Importance of Quality Seal Replacement

When a seal fails, the process of industrial seal replacement must be done with the same care as the initial installation. It is a false economy to replace a high-quality engineered seal with a cheap, inferior part. The cost of equipment downtime and potential damage almost always outweighs the small savings on the component itself. Replacing a failed seal with an identical, high-quality component from a trusted supplier like QZSEALS ensures a return to reliable operation and completes the lifecycle, paving the way for the next industrial seal’s journey to begin.

Conclusion: A Partner for the Entire Journey

The journey of an industrial seal—from a set of abstract requirements to a physical guardian of performance—is a story of precision engineering and material science. Understanding this complete lifecycle provides a deeper appreciation for these small but mighty components. It highlights that success is not just about the seal itself but also about the process of defining the challenge, selecting the right solution, installing it with care, and replacing it intelligently.

A comprehensive guide to industrial sealing best practices can be found on the Fluid Sealing Association website, covering material selection, installation, and maintenance tips.

At QZSEALS, our mission is to be your partner throughout this entire journey. We provide the technical consultation needed at the conception stage, the engineering and manufacturing excellence required for creation, and the high-quality, reliable products needed for operation and replacement. By focusing on innovative and cost-effective sealing solutions, we help our customers in the world’s most critical industries achieve the safety, reliability, and performance essential for their success. Contact us to learn how we can support you at every stage of your sealing journey.