In the world of extreme sealing, metal C ring seals are not just passive components; they are active mechanical springs designed to fight against leaks in the harshest environments known to engineering. At QZSEALS, we often see that while engineers choose the right seal, they often overlook the nuances of installation and configuration.

Unlike elastomeric O-rings that are forgiving, metal seals demand precision. A metal C ring seals function by balancing three forces: the clamping load of the flange, the internal pressure of the system, and the inherent springback elastic recovery of the metal, ensuring sustained sealing force even after load relaxation or thermal cycling. This guide dives into the critical engineering factors that determine whether your seal holds vacuum or fails catastrophically.

1. The Critical Rule: Orientation Matters

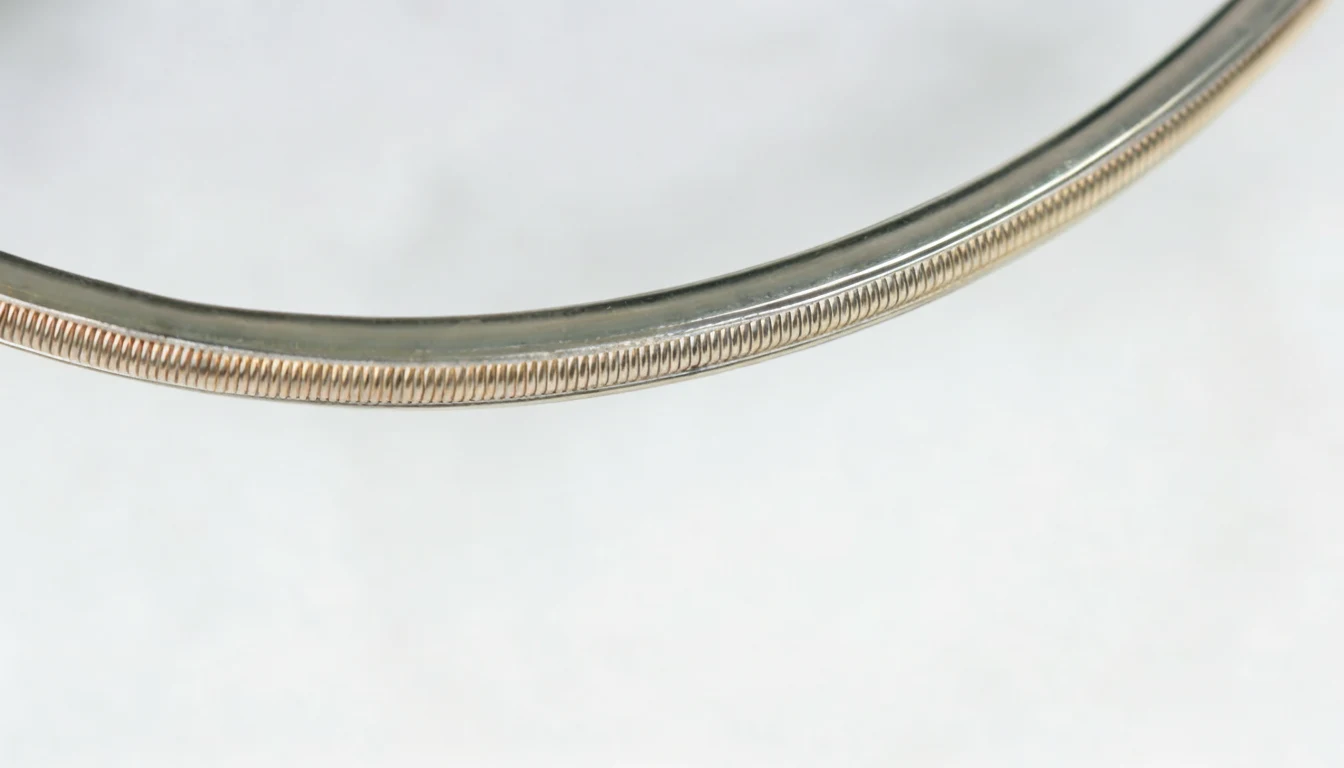

The most distinct feature of metal C ring seals is their open cross-section. This is not just for weight reduction; it is for pressure activation. However, this design introduces a failure mode that does not exist with solid rings: Directionality.

We manufacture two distinct types of C-rings based on pressure direction, and installing them backward is the number one cause of field failure:

- Internal Pressure C Rings (Internal Pressure Metal Seals): The open side of the “C” faces inwards (towards the center). The system pressure enters the C-cavity and pushes the seal legs outward against the flange surface. This makes the seal “self-energizing.”

- External Pressure C Rings (External Pressure Metal Seals) : The open side of the “C” faces outwards. This is critical for vacuum chambers or submarine applications where the higher pressure is on the outside. If you use an internal-style ring here, the external pressure will crush the “C” closed, causing a leak.

Ensure you select the correct configuration from our metal C-rings specifications.

2. The Science of Springback (Elastic Recovery)

Why choose a C-Ring over a metal O-ring? The answer lies in “Springback.”

In applications like jet engines or exhaust manifolds, flanges heat up and expand, causing the gap between them to grow (flange separation). A rigid seal would lose contact and leak. Metal C ring seals offer high elastic recovery. As the flange separates, the C-Ring expands to maintain contact.

Engineering Insight: C-Rings typically offer greater springback than hollow metal O-rings, making them the superior choice for applications with significant thermal cycling (e.g., -200°C to +600°C).

3. The Role of Plating and Surface Finish

Metal is hard. Even a polished steel flange has microscopic peaks and valleys. If you press a bare Inconel C-Ring against a steel flange, gas molecules will find a path through those microscopic gaps.

This is why metal seal plating types play a critical role in achieving reliable sealing performance. To overcome surface imperfections, a “soft” layer is applied over the hard base metal—this is the plating. Under compression, the plated layer flows plastically into the flange’s microscopic irregularities, creating a tight, leak-free seal.

Common Plating Options:

- Silver: The industry standard for high-temperature flange sealing applications (up to 450 °C). Silver offers excellent ductility and gap-filling properties, allowing it to plastically deform and seal microscopic flange imperfections under high temperature and pressure.

- Gold: Used for inert environments and ultra-low leakage requirements where no oxidation can occur.

- PTFE: Used for chemical resistance where metal plating might react, though temperature limited.

Note on Surface Finish: Because the plating does the sealing, the flange finish must be precise. For Metal C-Ring Seals, we generally recommend a concentric machined finish of 0.4 to 0.8 Ra (16-32 RMS). These requirements are consistent with general flange sealing and surface roughness guidelines published in engineering surface finish standards (Ra vs RMS).If the surface is too smooth, the plating may slide; if it is too rough, the plating will not properly conform and seal.

4. Load Considerations

One major advantage of metal C-ring Seals is that they require lower clamping force compared to solid metal gaskets. This allows manufacturers to use lighter flanges and smaller bolts—a crucial weight-saving factor in aerospace.

However, “lower load” does not mean “low load.” You must ensure your bolt torque is calculated to fully compress the seal to its designed height. Failing to reach the “seating load” means the plating will not deform properly. For heavier duty applications requiring higher loads, you might explore our broader metal sealing rings category.

Summary: Precision is Key

Metal C ring seals are the unsung heroes of the high-performance world. They bridge the gap between the flexibility of a spring and the durability of a weld. By paying attention to the orientation (internal vs. external) and respecting the surface finish requirements, you can achieve a leak-free system in environments where no rubber seal could survive.

If your application involves ultra-high vacuum, cryogenic temperatures, or extreme thermal cycling, we recommend reading our related article, The Metal C-Ring: Sealing Solutions for Extreme Vacuum and Temperature, for application-specific insights.