O-ring cord plays a critical role when sealing applications move beyond standard sizes. In the ideal world of engineering, every groove is machined to a standard ISO 3601 or AS568 dimension, and every replacement seal is sitting on the shelf. In the real world of maintenance and manufacturing, however, this is rarely the case. You often need custom diameter seals made from O-ring cord to handle non-standard groove diameters, massive flanges that exceed mold sizes, or urgent “machine down” situations where waiting weeks for a custom mold is impossible.

This is where O-Ring Cord becomes the hero of the workshop. At QZSEALS, while we pride ourselves on our precision molded parts, we also produce kilometers of high-quality extruded cord stock. This guide explains how to utilize this versatile material to solve sealing headaches that molded rings simply cannot.

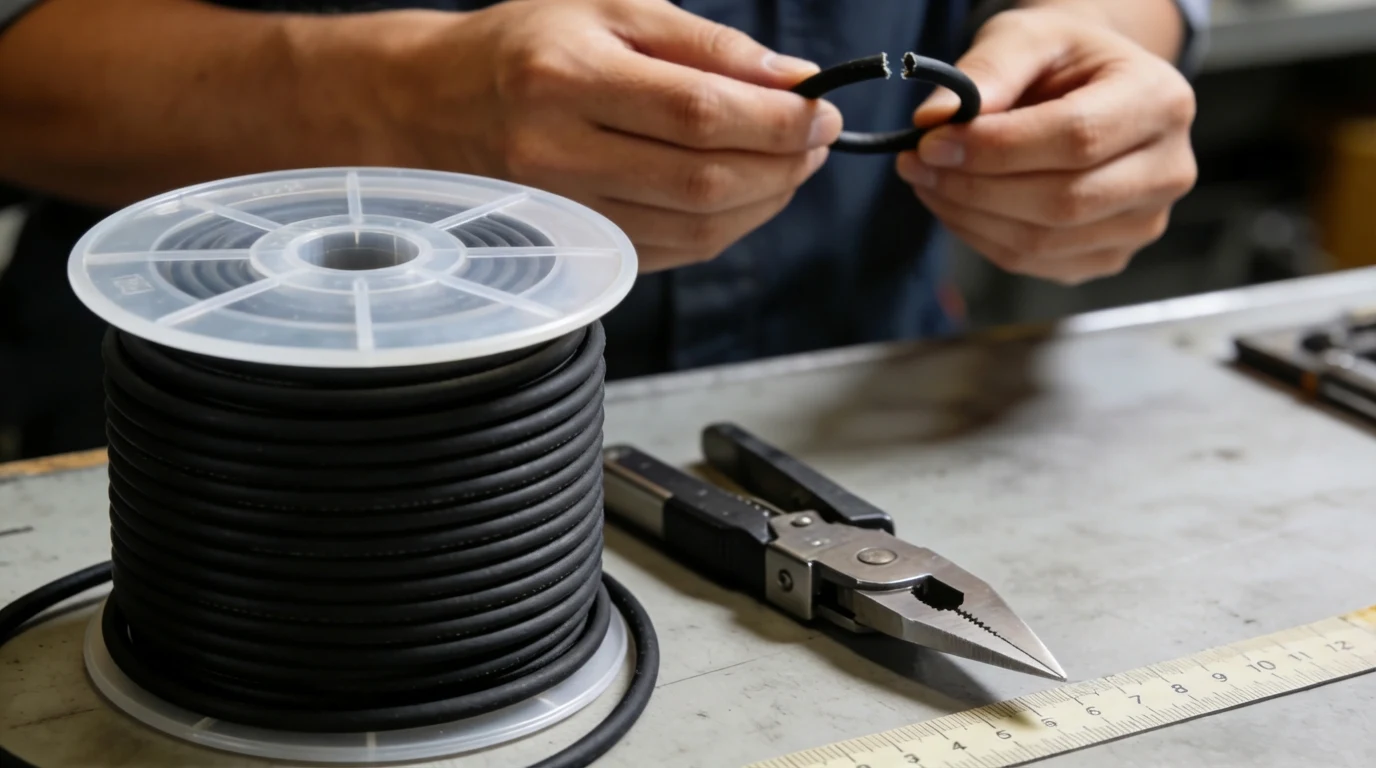

What is O-Ring Cord?

Unlike a molded O-ring which is created in a specific circular die, O-ring cord is produced via continuous extrusion. It is essentially an O-ring with no beginning and no end—until you cut it.

We supply it on spools in various cross-section diameters (e.g., 1.78mm, 5.7mm, up to large heavy-duty sizes). This allows you to fabricate a seal of any diameter, from a few centimeters to several meters, simply by cutting the length and joining the ends.

Explore our inventory here: O-Ring Cord Category.

When to Use O-Ring Cord (And When Not To)

It is crucial to understand the limitations. An extruded cord does not have the same unified physical structure as a molded ring. Based on our testing data, here is the rule of thumb:

The “Green Light” – Ideal Applications

- Large Static Flanges: For lids, container seals, or pipe flanges where the diameter is huge (e.g., >500mm). Molding tools for these sizes are prohibitively expensive.

- Emergency Seal Repair Kit: When a machine is leaking and you don’t have the part number. You can measure the groove, cut the cord, and fix it in minutes.

- Non-Standard Grooves: When the hardware design doesn’t match any standard chart.

The “Red Light” – Avoid Use

- Dynamic Applications: Do not use cord for pistons or rotating shafts. The joint (splice) is a hard spot that will suffer from friction fatigue and fail rapidly. For these, use proper piston seals or oil seals.

- High Vacuum/High Pressure: Air or gas can sometimes permeate through a glued joint.

The Joining Method: Glued vs. Vulcanized

How you join an O-ring cord matters. Understanding how to join an O-ring correctly is critical to seal performance, especially for large-diameter and non-standard applications. There are two common methods to turn an O-ring cord into a closed ring.

1. Cold Bonding (Super Glue)

This is the field repair method. You use a cyanoacrylate adhesive. It is fast and cheap.

Pros: Instant fix on-site.

Cons: The glue is hard and brittle. It has poor chemical and heat resistance compared to the rubber. If the glue fails, the seal fails.

2. Hot Vulcanization (Factory Made)

At QZSEALS, we manufacture spliced O-rings using a vulcanized splicing process. We cut the O-ring cord to the required length, apply a raw rubber compound to the ends, and place the joint into a heated die for vulcanization.

Pros: The joint becomes chemically bonded rubber. It is nearly as strong as the cord itself and retains flexibility.

Cons: Requires factory equipment.

If you need reliable large-diameter seals, ask us for vulcanized rings with a vulcanized O-ring joint, made from our O-ring cord stock.

Material Options for Rubber Cord Stock

Just like molded rings, we extrude cord in various polymers to match your chemical environment.

- NBR (Nitrile) Cord: The standard for general industrial oil and water applications.

- FKM (Viton) Cord: Essential for high-temperature maintenance jobs. If you are repairing a kiln or an engine seal, use this.

- Silicone Cord: Often used for large light-fitting seals or low-closure-force enclosures due to its softness.

- EPDM Cord: Widely used for hot water, steam, and outdoor applications. Excellent resistance to weathering, ozone, and aging, making it suitable for HVAC systems and water treatment equipment.

- PTFE Cord: Unlike rubber, PTFE cannot be glued. It is often used as a valve stem packing material. We offer solid PTFE cord and 3.2mm PTFE round cord for chemically aggressive environments.

![]()

How to Calculate Cut Length

If you are making your own ring, accuracy is key. Do not just wrap it around the groove and cut. You must calculate the Cut Length (L) based on the Neutral Axis.

The Formula:

L = (Groove Diameter + Cross Section) × 3.1416

It is usually better to cut slightly longer (1-2%) to ensure the cord is in compression (pushed together) rather than tension (pulled apart) when installed. Tension causes joints to pop open.

Alternatives to Rubber Cord

In some heavy industrial valves or pumps, a rubber cord might extrude. In these cases, you might look at braided packing.

For example, high pressure graphite gland packing rope is effectively a “cord” made of woven fibers and graphite, designed for dynamic sealing in pumps where rubber O-ring cords would fail.

Conclusion

O-Ring cord is the “Swiss Army Knife” of the sealing world and one of the most versatile forms of extruded rubber profiles. It empowers maintenance teams to solve leaks instantly and allows engineers to seal massive equipment without tooling costs.

Whether you need a spool of custom rubber cord for your workshop inventory or a pre-vulcanized large-diameter ring, QZSEALS delivers precision extrusion with tight tolerances. Always keep a few meters of NBR and FKM cord in stock—it will save your production line one day.