Casing Material

| Material | Description | Operating Temperature |

| FEP | Copolymer of hexafluoropropylene and tetrafluoroethylene; similar to PTFE but melt-processable for molding & extrusion. | –60°C ~ +205°C |

| PFA | Copolymer of tetrafluoroethylene and perfluoroethers; clear, durable, and performs better at high temperatures. | –60°C ~ +260°C |

Core Material

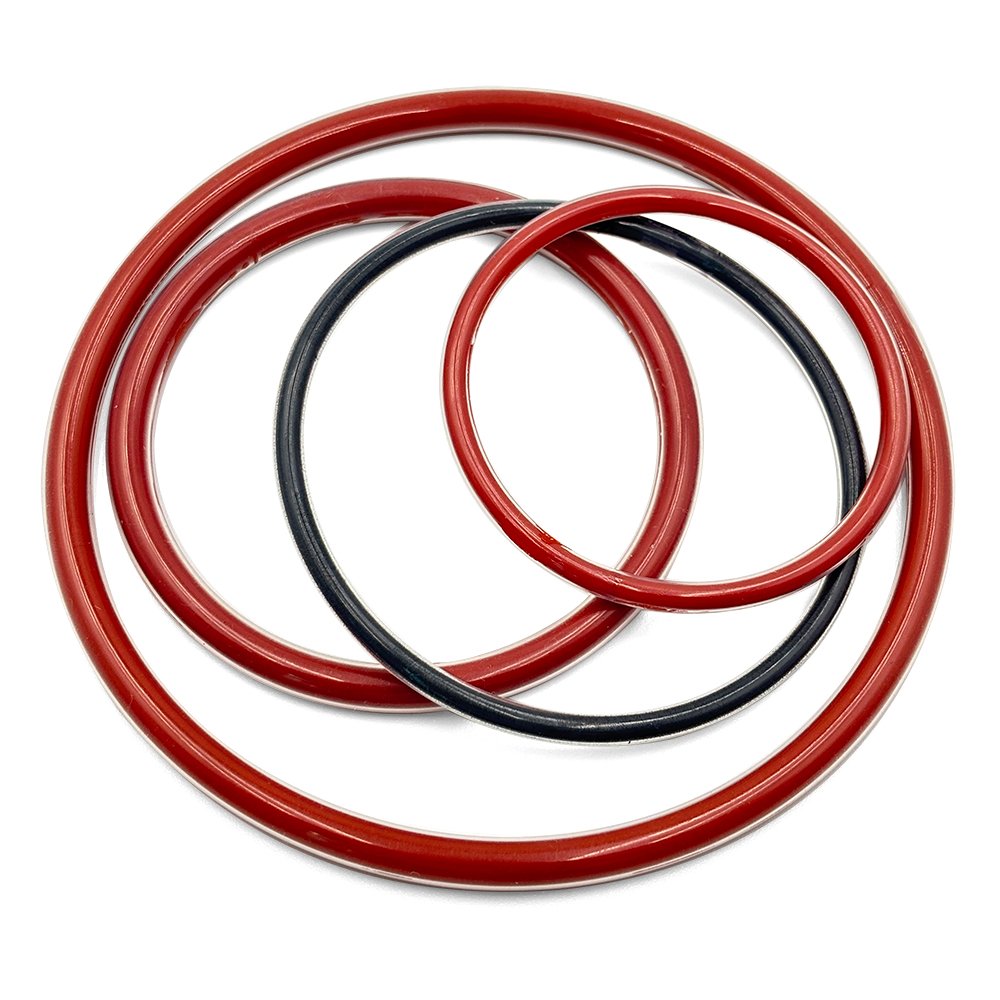

Encapsulated O-rings use a rubber core made from Fluorocarbon (FKM) or Silicone (VMQ).

Both solid and hollow designs are available — hollow cores provide greater flexibility and lower compression force.

Features

- Durable & Wear-Resistant: Longer lifespan than standard rubber O-rings.

- Chemical Stable: Resistant to most chemicals, with exceptions for alkali metals, fluorine, and certain halides at high temperatures.

- Rubber-Like Elasticity: Maintains flexibility for reliable sealing.

- Low Friction & Gas-Tight: FEP/PFA surface has very low friction (0.1–0.2) and excellent gas barrier properties.

- Suitable for Harsh Environments: Performs well under extreme temperatures, pressures, and aggressive media.

Application

- Pumps and Valves

- Heat Exchangers

- Filters

- Pipelines

- Gas Compressors

Specifications

Encapsulated O ring is produced via extrusion, allowing for almost any diameter and cross-section with greater flexibility than fully molded O-rings.

As an experienced encapsulated O-ring manufacturer, QZSEALS supplies both FEP encapsulated O-rings and PFA encapsulated O-rings tailored to specific operating conditions.

Contact us today to request a quote for more details of encapsulated O ring!

Reviews

There are no reviews yet.