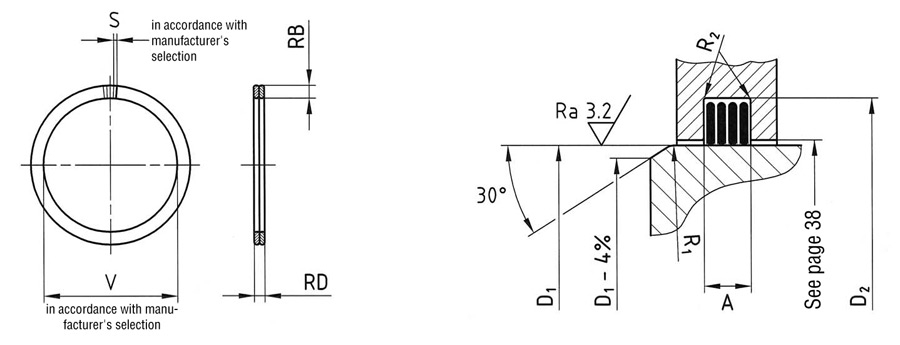

The FK 6 ISD double laminar sealing rings consist of two rings combined into one set (2 rings = 1 set) and are installed with inside clamping on the shaft. This double-wound construction provides uniform radial tension around the shaft and ensures stable, consistent contact pressure during operation.

Compared with single laminar sealing rings such as the FK3 types, the FK 6 ISD design eliminates the axial joint gap, significantly reducing potential leakage paths and improving overall sealing reliability. When properly greased, these double laminar sealing rings form an effective labyrinth seal that both retains lubricant and blocks external contaminants.

In operation, FK 6 ISD laminar sealing rings effectively:

Prevent grease leakage

Block dust and dirt ingress

Protect against splash water

Improve sealing reliability in heavily contaminated environments

For applications with even higher sealing requirements, the combined ring sets FK 6 ISKD (with additional sealing of the groove base diameter) further increase the labyrinth effect and optimize the sealing performance, making them suitable for extremely demanding industrial conditions.

Materials

- Stainless steel 304

- Stainless steel 316

Features

1. Double wound design for uniform radial tension

2. No axial joint gap, unlike single-wound laminar sealing rings

3. Excellent protection against dust, dirt, and splash water

4. Reliable grease retention for roller and plain bearings

5. Enhanced labyrinth sealing effect (especially with FK 6 ISKD sets)

6. Designed for high-contamination environments

7. Long service life and stable performance in demanding conditions

Applications

Roller bearings and plain bearings

Shafts requiring high-performance grease sealing

Mixers, agitators, and rotating equipment

Slurry pumps and heavy-duty industrial machinery

Pulp & paper, mining, cement, and process industries

Connector assemblies with pressure-balanced cavities and contamination protection

In connector applications, the seal arrangement can be custom designed to provide optimal protection against contamination. Gases may build up pressure in a center cavity, which is protected on both ends from contaminants entering, ensuring clean gas flow into and out of the cavity.

Working Environment

High contamination conditions

Presence of fine particles, dust, and gases

Exposure to grease, moisture, and splash water

Applications requiring reliable and long-term sealing performance

Available Laminar Sealing Ring Types

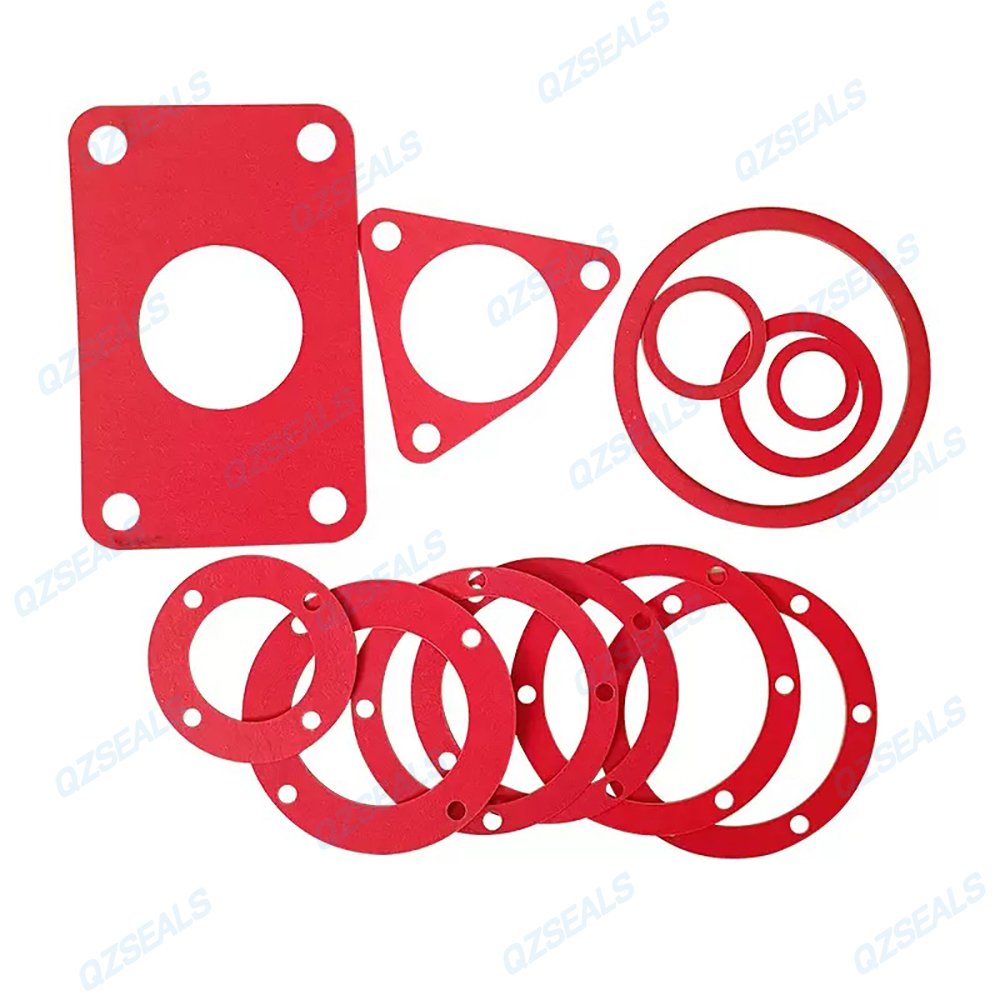

In addition to FK 6 ISD Double Laminar Sealing Rings for Shafts, we also supply a full range of laminar sealing rings for both bores and shafts, including single and double laminar designs.

| FEY | Ring Type | Application |

| FK3 AS | Single laminar sealing rings | For bores |

| FK3 ASK | Single laminar sealing rings | For bores |

| FK3 IS | Single laminar sealing rings | For shafts |

| FK3 ISK | Single laminar sealing rings | For shafts |

| FK6 ASD | Double laminar sealing rings | For bores |

| FK6 ASKD | Double laminar sealing rings | For bores |

| FK6 ISD | Double laminar sealing rings | For shafts |

| FK6 ISKD | Double laminar sealing rings | For shafts |

This product range allows us to offer suitable laminar sealing ring solutions for different installation conditions, whether for bores or shafts, and for both standard and higher sealing performance requirements.

Custom sizes and configurations can also be supplied according to your application needs.

Reviews

There are no reviews yet.