Hollow Metal O Ring Material

Hollow Metal O Ring Seal Material Option & Comparison

Selecting the right metal for sealing applications is essential to achieving optimal performance under demanding temperature, pressure, and chemical conditions. Each alloy offers its own balance of strength, elasticity, and corrosion resistance.

| Material | Main Features | Typical Temp. |

| SS321 | Titanium-stabilized; good resistance to intergranular corrosion and high-temp oxidation. | ≤ 370 °C |

| SS304 | General-purpose stainless steel; good corrosion resistance and cost-effective. | ≤ 425 °C |

| SS316 | Added Mo improves pitting & chloride resistance; ideal for chemical use. | ≤ 480 °C |

| Inconel 718 | Nickel-based alloy with excellent strength, oxidation & creep resistance. | ≤ 700 °C |

| Inconel X-750 | Superior tensile & corrosion resistance; maintains elasticity at high temp. | ≤ 975 °C |

Coating Option & Comparison

Copper is a soft and conductive coating material that improves contact conformity and reduces microscopic leakage. It provides moderate corrosion protection and excellent thermal transfer, making it suitable for general industrial applications and lubricated sealing systems.

| Coating | Function & Advantages | Notes |

| Silver | Good oxidation resistance and ductility; suits high-temp sealing. | Balanced cost & performance |

| Gold | Excellent corrosion resistance and softness; ideal for extreme conditions. | Most expensive |

| Copper | Soft, good thermal transfer; fills micro-surface gaps. | Common industrial use |

| Nickel | Hard, wear-resistant layer; protects against corrosion & heat. | For high-pressure seals |

| Tin | Soft coating ensuring tight seal under low compression. | Cost-effective option |

| Teflon (PTFE) | Low friction, chemical inertness, and anti-stick surface. | For aggressive environments |

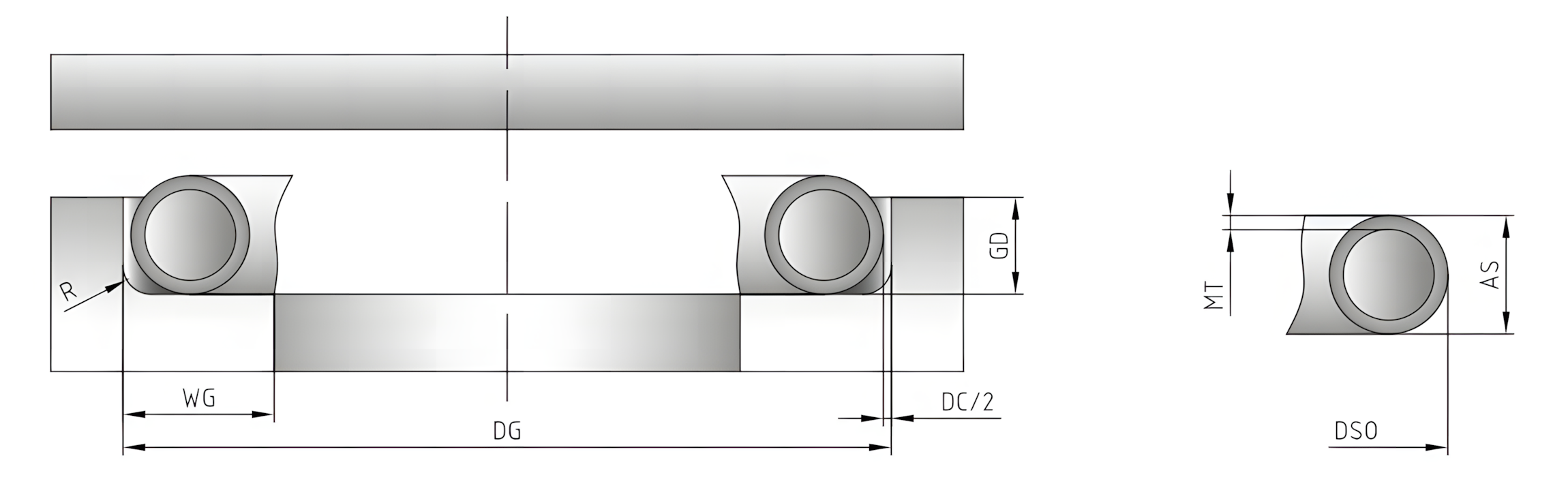

Hollow Metal O Ring Selection Table

| DG | GD | WG | DSO | AS | MT | DC | ||||

| Outer range | Groove Depth | Tolearance | Groove width | Seal OD Diameter | Seal OD Diameter | Height | Tolerance | Material Thickness 1 | Material Thickness 2 | Diameter Clearance |

| 6.00-25.00 | 0.72 | +/-0.03 | 1.4 | 0.00 | 0.08 | 0.9 | +/-0.04 | 0.15 | 0.15 | 0.15 |

| 10.00-50.00 | 0.96 | +/-0.05 | 1.8 | 0.00 | 0.10 | 1.2 | +/-0.05 | 0.20 | 0.30 | 0.20 |

| 12.00-200.00 | 1.28 | +/-0.05 | 2.3 | -0.05 | 0.13 | 1.6 | +/-0.05 | 0.25 | 0.35 | 0.20 |

| 25.00-200.00 | 1.92 | +/-0.05 | 3.2 | -0.05 | 0.13 | 2.4 | +/-0.05 | 0.25 | 0.50 | 0.20 |

| 50.00-400.00 | 2.56 | +/-0.05 | 4.0 | -0.08 | 0.13 | 3.2 | +/-0.05 | 0.35 | 0.50 | 0.30 |

| 75.00-650.00 | 3.20 | +/-0.05 | 5.0 | -0.08 | 0.13 | 4.0 | +/-0.05 | 0.40 | 0.50 | 0.30 |

| 100.00-800.00 | 3.84 | +/-0.05 | 6.4 | -0.10 | 0.13 | 4.8 | +/-0.05 | 0.50 | 0.65 | 0.40 |

| 200.00-1200.00 | 5.12 | +/-0.05 | 8.8 | -0.10 | 0.13 | 6.4 | +/-0.08 | 0.65 | 0.80 | 0.40 |

| 300.00-2000.00 | 7.68 | +/-0.08 | 12.8 | -0.13 | 0.15 | 9.6 | +/-0.08 | 1.00 | 1.30 | 0.80 |

| 800.00-3000.00 | 10.24 | +/-0.08 | 16.6 | -0.13 | 0.20 | 12.8 | +/-0.08 | 1.30 | 1.70 | 1.00 |

Contact us today to request a quote for hollow metal o ring sealing solutions!

Reviews

There are no reviews yet.