Metal C Rings Types

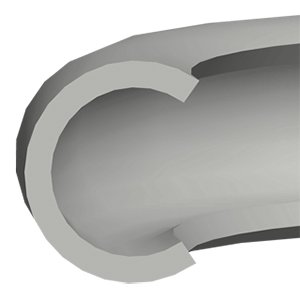

Metal C Ring for Axial Pressure: a sturdy axial seal designed to withstand pressures corresponding to axial operating conditions. It is an optimal solution for static and low-cycle dynamic axial sealing applications, offering reliable performance in a wide range of industrial environments, including hydraulic systems and high-temperature shaft sealing.

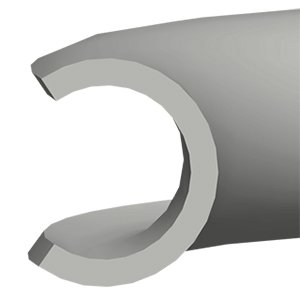

Metal C Ring for Internal Pressure: a resilient static face seal designed for internally pressurized applications, featuring an inward-facing open profile. It is capable of withstanding operating pressures equal to internal system pressure and is well suited for demanding uses such as assemblies, pressure vessels, jet engines, fuel injectors, and lightweight flange connections.

Metal C Ring for External Pressure: a robust static face seal designed for externally pressurized applications, featuring an outward-facing open profile. It is capable of withstanding operating pressures equal to external system pressure, while providing good springback characteristics to accommodate thermal cycling and dimensional changes.

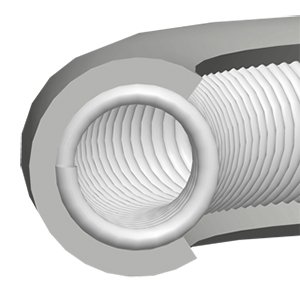

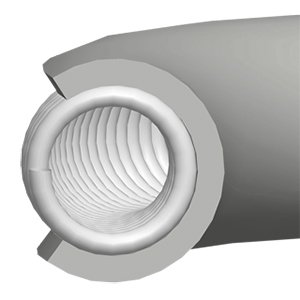

Metal C Ring spring energized for Axial Pressure: this seal is engineered to withstand higher axial loads and is well suited for applications with relatively rough mating surfaces. It is mainly used for static and low-cycle axial sealing applications. The integrated spring reinforcement improves sealing efficiency and elastic recovery, ensuring reliable performance in demanding operating conditions.

Metal C Ring, spring energized for Internal Pressure: this seal is designed to withstand high loads and perform reliably on rough or uneven mating surfaces. It is widely used in demanding applications such as pressure vessel closures, manways, hand-holes, steam generators, gasoline and diesel engine fire rings, and exhaust joints. Owing to its ability to accommodate non-flat flange surfaces, it is often the preferred solution for internally pressurized joints. Although primarily intended for internal pressure sealing, it may also be applied in externally pressurized systems to prevent process media from entering the seal cavity, with a correspondingly lower allowable working pressure.

Metal C Ring, spring energized for External Pressure: this seal is designed to accommodate high loads and perform reliably on rougher mating surfaces. It is primarily intended for externally pressurized joints and flanges with less refined surface finishes. In addition, it can be applied in internally pressurized systems to prevent process media from entering the seal cavity, though with a reduced allowable working pressure.

Metal C Rings Material

Choosing the right material for metal C rings require a thorough understanding of the distinct characteristics, performance advantages, and limitations of the available metal options.

| Material | Main Features | Typical Temp. |

| SS321 | Titanium-stabilized; good resistance to intergranular corrosion and high-temp oxidation. | ≤ 370 °C |

| SS304 | General-purpose stainless steel; good corrosion resistance and cost-effective. | ≤ 425 °C |

| SS316 | Added Mo improves pitting & chloride resistance; ideal for chemical use. | ≤ 480 °C |

| Inconel 718 | Nickel-based alloy with excellent strength, oxidation & creep resistance. | ≤ 700 °C |

| Inconel X-750 | Superior tensile & corrosion resistance; maintains elasticity at high temp. | ≤ 975 °C |

Coating Option & Comparison

Applying a coating or electroplating to metal C rings improve surface adhesion and creates a more ductile (softer) outer layer, enabling the seal to conform to microscopic imperfections in the groove or flange surfaces.

During compression, the coating flows into and fills these microscopic surface irregularities, resulting in effective metal-to-surface contact and excellent sealing performance. The level of tightness, typically evaluated by the leakage rate, depends on the interaction between the metal C rings and the surface finish of the mating components.

The required coating type and thickness are determined by the target leakage rate and the surface quality of the groove and flange. To ensure reliable sealing, the coating must be properly matched to the applied compressive load of the metal C ring.

| Coating | Function & Advantages | Notes |

|---|---|---|

| Silver | Good oxidation resistance and ductility; suits high-temp sealing. | Balanced cost & performance |

| Gold | Excellent corrosion resistance and softness; ideal for extreme conditions. | Most expensive |

| Copper | Soft, good thermal transfer; fills micro-surface gaps. | Common industrial use |

| Nickel | Hard, wear-resistant layer; protects against corrosion & heat. | For high-pressure seals |

| Tin | Soft coating ensuring tight seal under low compression. | Cost-effective option |

| Teflon (PTFE) | Low friction, chemical inertness, and anti-stick surface. | For aggressive environments |

QZSEALS provides professional sealing solutions supported by experienced technical engineers. Based on each customer’s specific operating conditions—such as media compatibility, temperature range, pressure level, and application environment—we offer tailored recommendations to ensure reliable and long-term sealing performance.

postmaster@qzsealings.com –

High temperature & corrosion resistant metal C-rings