Metal O-Rings Types

| Type of Metal O-Ring | Description / Features | Pressure / Temperature | Special Notes |

Standard Type | Made from metallic tubing or solid wire; economical option. Not self-energizing or pressure-filled. | Vacuum up to 0.68 MPa (low to moderate pressure). | Best for cost-effective sealing where pressure is not high. |

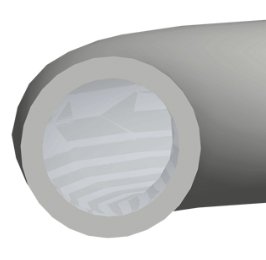

Self-energizing Type | Features borings/grooves on ID or OD; system pressure acts directly on the O-ring to boost sealing force. | 0.68MPa and above (uses system pressure to enhance sealing). | Ideal for higher-pressure systems requiring increased sealing performance. |

Pressure-filled Type | Contains gas filling (~4 MPa+); gas expands with temperature, increasing sealing force. | Vacuum to approx. 2 MPa; High temperature 425°C~975°C. | Lower pressure resistance than self-energizing type but excellent for high-temperature applications. |

Metal O-Rings Materials

Selecting the right metal o-rings materials for sealing applications is essential to achieving optimal performance under demanding temperature, pressure, and chemical conditions. Each alloy offers its own balance of strength, elasticity, and corrosion resistance.

| Material | Main Features | Typical Temp. |

| SS321 | Titanium-stabilized; good resistance to intergranular corrosion and high-temp oxidation. | ≤ 370 °C |

| SS304 | General-purpose stainless steel; good corrosion resistance and cost-effective. | ≤ 425 °C |

| SS316 | Added Mo improves pitting & chloride resistance; ideal for chemical use. | ≤ 480 °C |

| Inconel 718 | Nickel-based alloy with excellent strength, oxidation & creep resistance. | ≤ 700 °C |

| Inconel X-750 | Superior tensile & corrosion resistance; maintains elasticity at high temp. | ≤ 975 °C |

Coating Option & Comparison

Copper is a soft and conductive coating material that improves contact conformity and reduces microscopic leakage. It provides moderate corrosion protection and excellent thermal transfer, making it suitable for general industrial applications and lubricated sealing systems.

| Coating | Function & Advantages | Notes |

| Silver | Good oxidation resistance and ductility; suits high-temp sealing. | Balanced cost & performance |

| Gold | Excellent corrosion resistance and softness; ideal for extreme conditions. | Most expensive |

| Copper | Soft, good thermal transfer; fills micro-surface gaps. | Common industrial use |

| Nickel | Hard, wear-resistant layer; protects against corrosion & heat. | For high-pressure seals |

| Tin | Soft coating ensuring tight seal under low compression. | Cost-effective option |

| Teflon (PTFE) | Low friction, chemical inertness, and anti-stick surface. | For aggressive environments |

Heat Treatment for Metal O-Rings

At QZSEALS, our metal O-rings can be processed with different heat-treatment methods depending on the material and application requirements. Proper heat treatment significantly improves both performance and service life in demanding sealing environments.

Enhanced Mechanical Strength

Heat treatment improves key mechanical properties such as hardness, toughness, and tensile strength. These enhancements result in greater durability and improved wear resistance—critical for metal O-rings operating under high pressure or elevated temperatures.

Stress Relief for Long-Term Stability

Metal forming and machining can introduce internal stresses that may lead to distortion or premature failure during operation. Through controlled heat-treatment processes, these stresses are effectively relieved, ensuring the O-ring remains stable and reliable throughout its lifespan.

Improved Corrosion Resistance

Certain heat-treatment techniques also increase the metal’s resistance to corrosion. This is particularly beneficial when O-rings are used in environments containing moisture, chemicals, or other aggressive media.

Superior Dimensional Stability

Proper heat treatment helps maintain the dimensional accuracy of the O-ring even when exposed to wide temperature fluctuations. This ensures consistent sealing performance in both cryogenic and high-temperature applications.

Ring Diameter & Tube Wall Thickness

The selection of tube wall thickness is closely connected to the ring’s outer diameter, the required sealing load, and the design space available within the system.

To ensure reliable sealing performance, the wall thickness must be optimized so that the ring achieves the correct elastic deformation under operating pressure. Proper deformation generates the necessary sealing force without overstressing the material.

Below are the recommended standard wall thickness options, suitable for use across a wide range of ring diameters.

| Tube outside diameter [mm] | Ring outside diameter [mm] | Standard tube wall thicknesses [mm] | |

| min. | max. | ||

| 0.9 | 6.4 | 101 | 0.15 |

| 1.6 | 15.9 | 254 | 0.25 / 0.30 / 0.36 |

| 2.4 | 25.4 | 508 | 0.25 / 0.46 |

| 3.2 | 50.8 | 1016 | 0.25 / 0.51 / 0.64 |

| 4.0 | 76.2 | 1270 | 0.51 / 0.64 |

| 4.8 | 101 | 1524 | 0.51 / 0.81 |

| 6.4 | 127 | 2500 | 0.64 / 0.81 |

Important Considerations

For seals with electroplated surfaces and a tube wall thickness of 3.2 mm, a load of around 72 N/mm along the circumference is sufficient to cause plastic deformation of the plating layer.

For uncoated tubes with a 3.2 mm wall diameter, approximately 140 N/mm is required to achieve similar deformation.

Teflon/PTFE-coated rings deform plastically under a much lower load—around 18 N/mm along the circumference—due to the softer coating characteristics.

Groove dimensions

The appropriate size and finish quality of the groove are as crucial as the Metal O-ring itself for the seal’s application.

The suggested groove dimensions for internal and external pressure applications below should be considered general guidelines for preparing sealing surfaces.

| tube outside dia. [mm] | groove depth [mm] min. max. | groove width [mm] min. | ring tolerance [mm] | spring-back [mm] | groove outside dia.[mm] (for interanl pressure) | groove inside dia.[mm] (for exteranl pressure) |

| 0.9 | 0.60-0.68 | 1.4 | 0.08 | ~ 0.05 | B+0.10 / 0.20 | A-0.10 / 0.20 |

| 1.6 | 1.15-1.25 | 2.3 | 0.08 | ~ 0.07 | B+0.10 / 0.20 | A-0.10 / 0.20 |

| 2.4 | 1.80-1.95 | 3.0 | 0.13 | ~ 0.07 | B+0.15 / 0.25 | A-0.15 / 0.25 |

| 3.2 | 2.40-2.60 | 4.0 | 0.13 | ~ 0.08 | B+0.20 / 0.35 | A-0.20 / 0.35 |

| 4.0 | 3.05-3.25 | 5.0 | 0.15 | ~ 0.10 | B+0.25 / 0.40 | A-0.25 / 0.40 |

| 4.8 | 3.70-3.90 | 6.2 | 0.18 | ~ 0.10 | B+0.25 / 0.40 | A-0.25 / 0.40 |

| 6.4 | 5.00-5.20 | 8.2 | 0.20 | ~ 0.13 | B+0.30 / 0.50 | A-0.30 / 0.50 |

The listed dimensions apply to rings without electroplating.

For rings with a 0.9 mm profile section, the groove depth should be increased by twice the coating thickness to accommodate the plating layer. However, for electroplated or coated rings with a tube diameter of 1.6 mm or larger, no additional groove depth is required.

The Finish of Metal O-rings

Recommended qualities of finish of the groove and the jointing face of the flange:

- 0.1 – 0.4 µm Ra – for uncoated rings

- 0.4 to 0.8 µm Ra – for electroplated or coated rings

Ghost lines on the groove surface or flange facing must be free of dirt, grinding dust, or other impurities.

- Coating O-Ring: Ra = 0.4 – 0.4 to 0.8 µm

- Uncoated O-ring: Ra = 0.1 – 0.4 µm Ra

Reviews

There are no reviews yet.