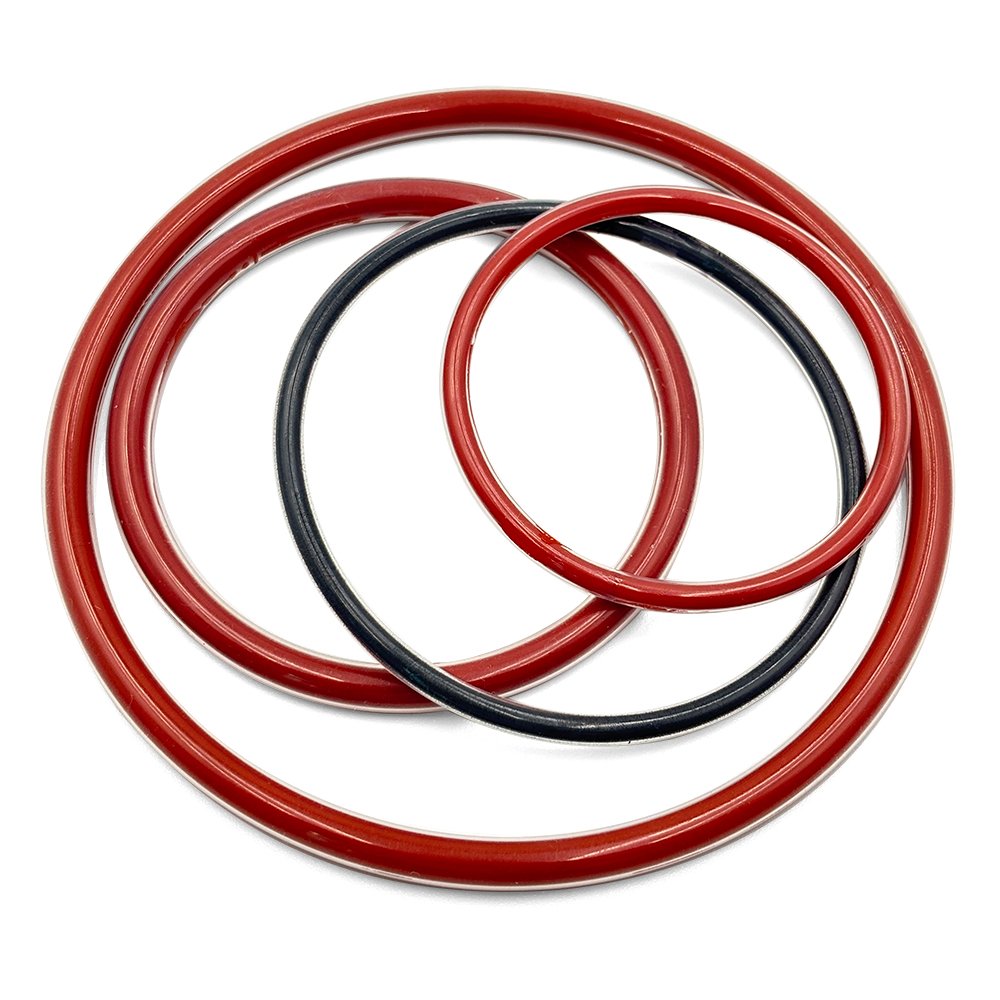

PFA encapsulated O ring is engineered for static sealing applications where conventional elastomer O-rings are unable to withstand aggressive chemicals, elevated temperatures, or stringent cleanliness requirements. Each O-ring consists of a resilient elastomeric core that is completely enclosed within a seamless PFA (Perfluoroalkoxy) jacket, forming a chemically inert and non-porous sealing barrier.

This construction combines the elastic recovery of rubber with the outstanding chemical and thermal resistance of fluoropolymers, ensuring long-term sealing reliability in critical industrial systems.

Material Options

| Core Material | Product Name | Characteristics | Applications |

| FKM | PFA encapsulated FKM O-rings / Viton O-rings | Excellent compression set resistance, good mechanical strength, long service life | Chemical processing, petrochemical systems, valves, pumps |

| Silicone | PFA encapsulated silicone O-rings | Softer core, superior flexibility, excellent high- and low-temperature performance | Semiconductor equipment, pharmaceutical systems, thermal cycling applications |

PFA encapsulated O-rings are available with different elastomeric cores to match specific operating requirements. PFA encapsulated FKM O-rings refer to the same product, as Viton is a commonly used trade name for FKM. Silicone cores are also available for applications requiring enhanced flexibility and temperature resistance. EPDM cores are not recommended due to heat-related limitations during the encapsulation process.

Material Properties and Performance Characteristics

PFA encapsulated O ring operates reliably over a wide temperature range from –60°C to +250°C. The PFA jacket provides resistance to almost all chemical substances, including strong acids, strong bases, salts, organic solvents, and corrosive process media.

In addition to chemical resistance, PFA offers high dielectric strength, resistance to atmospheric aging, low gas permeability, and a naturally low coefficient of friction. These characteristics make PFA encapsulated O-rings an ideal solution for applications where purity, durability, and chemical compatibility are essential.

Advantages of PFA Encapsulation O ring

Compared with standard elastomer seals and FEP encapsulated alternatives, PFA encapsulation provides enhanced performance in demanding environments. PFA offers improved mechanical strength at elevated temperatures, greater resistance to cracking, and a longer service life.

The low-friction, anti-adhesive surface of PFA minimizes wear, reduces contamination buildup, and supports hygienic operation in sensitive production processes.

Typical Applications and Industries

PFA encapsulated O-rings are widely used in the following industries:

Chemical processing

Pharmaceutical manufacturing

Semiconductor industry

Food and beverage processing

Petrochemical systems

Automotive manufacturing

Aerospace applications

Installation and Use Recommendations

Proper installation is critical to achieving the full service life of PFA encapsulated O ring. Many seal failures are caused by installation errors or improper groove design rather than material defects.

To reduce stress on the encapsulation during assembly, gentle heating—such as immersion in hot water—is recommended to temporarily increase flexibility. Installation surfaces should be free of sharp edges, burrs, or excessive roughness to prevent damage to the PFA jacket.

PFA encapsulated O ring is intended for static applications only and are not recommended for dynamic sealing or contact with abrasive media.

Custom Production of PFA Encapsulated O Ring

Custom-made PFA encapsulated O-rings are available to meet specific dimensional, material, and application requirements. Whether you require PFA encapsulated silicone O-rings or PFA encapsulated Viton O-rings, we provide precision manufacturing and strict quality control to ensure consistent sealing performance and durability in demanding industrial environments.

Reviews

There are no reviews yet.