QZSEALS

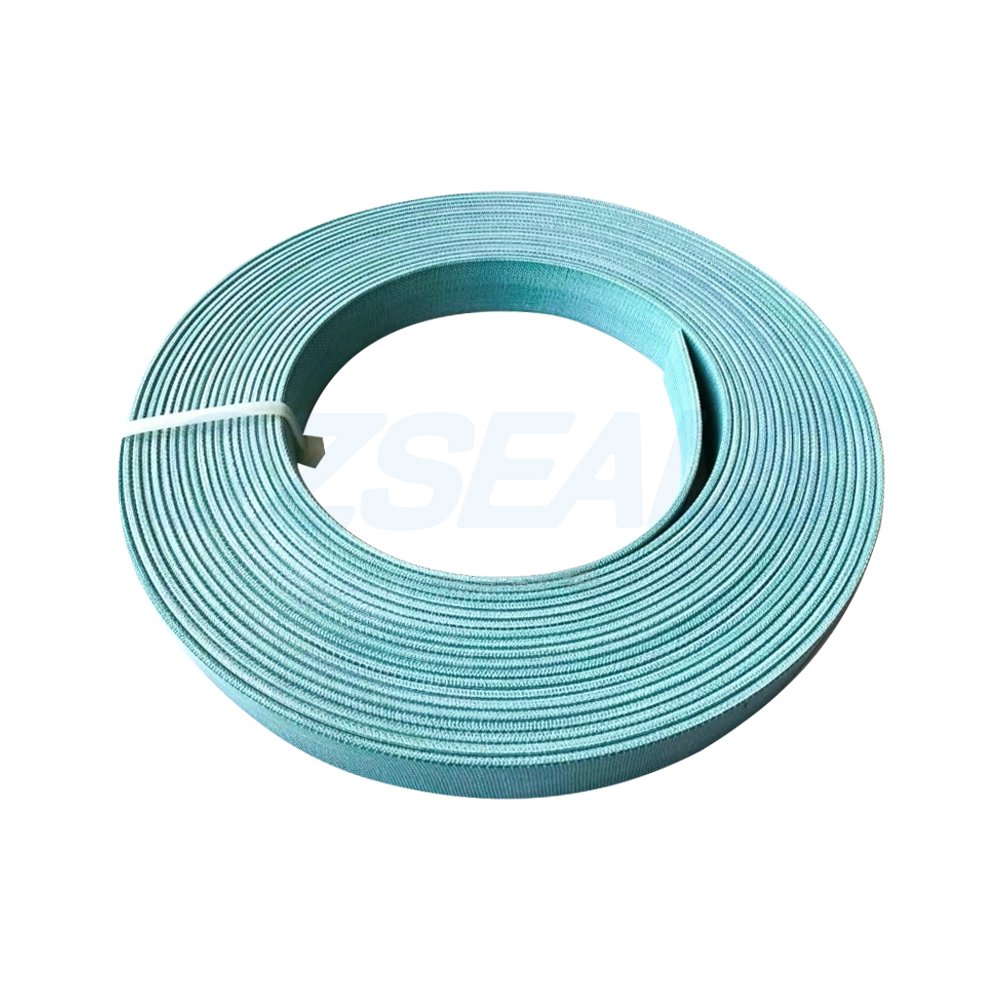

PTFE filled bronze guide tape—also known as GST wear strip—is engineered for guiding and supporting pistons and piston rods in reciprocating hydraulic cylinders. It provides precise linear guidance, absorbs radial loads, and prevents direct metal-to-metal contact inside the cylinder.

PTFE filled bronze guide tape features outstanding low-friction properties, excellent dry-running behavior, and high chemical stability. It is suitable for high-frequency, long-stroke, and high-temperature hydraulic applications.

As temperature increases, the allowable load capacity of PTFE materials decreases. For temperatures below 0°C, please consult us for technical evaluation

Technical Data

Speed: ≤ 15 m/s

Temperature: -180°C to +250°C

Pressure: ≤ 63 MPa

Media: Hydraulic oils, compressed air

Materials

PTFE filled with bronze (standard GST type)

PTFE filled with carbon

PTFE filled with carbon fiber

Applications

The guide tape is widely used in hydraulic and other reciprocating, oscillating, and slow-rotating systems. It is suitable for light-to-medium load applications with limited radial force.

Typical applications include:

Injection molding machines

Shock absorbers

Accumulators

Bulldozers & excavators

Forging presses & ceramic brick machines

Rolling mills & metallurgical equipment

Agricultural and forestry machinery

Conveying machinery

Chemical and marine equipment

Machine tools and construction machinery

Features

Excellent chemical and heat resistance

Outstanding wear resistance & long service life

Extremely low friction, no stick-slip effect

High load-bearing capability; prevents metal contact

Absorbs side loads & suppresses vibration

Allows increased extrusion gaps due to proper alignment

Good dust-tolerance; foreign particles can embed safely

Simple groove design and easy installation

Stable operation across wide media range

Available Sizes (Width × Thickness)

3*1.5mm

5.6*1.5mm

8.1*1.5mm

15*1.5mm

20*1.5mm

5*2mm

6*2mm

8*2mm

10*2mm

15*2mm

20*2mm

25*2mm

30*2mm

35*2mm

40*2mm

45*2mm

50*2mm

5.6*2.5mm

6.3*2.5mm

8*2.5mm

10*2.5mm

15*2.5mm

20*2.5mm

25*2.5mm

30*2.5mm

8*3mm

9.5*3mm

10*3mm

12.7*3mm

15*3mm

20*3mm

25*3mm

30*3mm

35*3mm

40*3mm

45*3mm

50*3mm

15*3.5mm

20*3.5mm

25*3.5mm

30*3.5mm

35*3.5mm

40*3.5mm

45*3.5mm

50*3.5mm

8*4mm

10*4mm

15*4mm

20*4mm

25*4mm

30*4mm

35*4mm

40*4mm

50*4mm

Contact us to find out the specific length of the roll for each size.

Why Choose Our GST Guide Tape?

Manufactured with patented extrusion technology

Full traceability with on-tape size markings

Precise cutting and machining capabilities

Strong wear resistance and long service life under extreme loads

Continuous strip form minimizes waste and reduces cost

Perfect for hydraulic cylinders in extreme industrial environments

Reviews

There are no reviews yet.