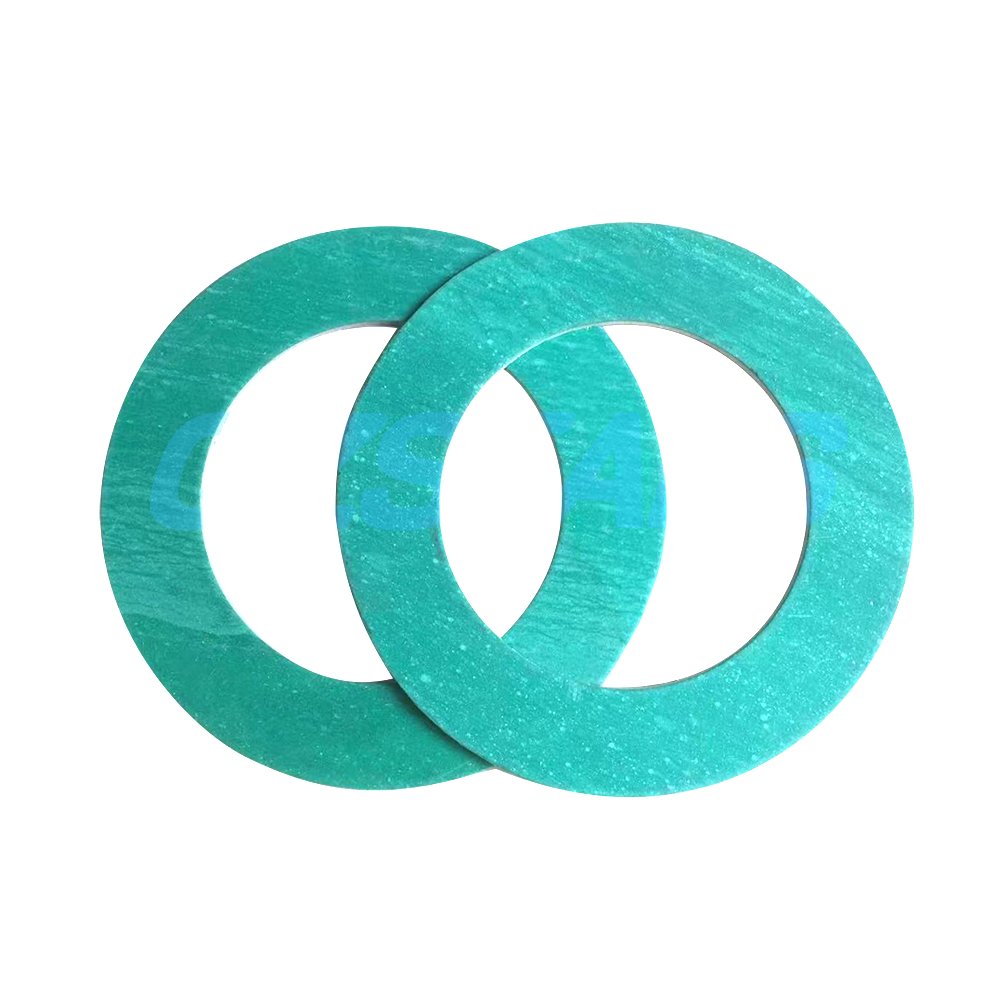

Technical data

Material: 100% Virgin PTFE, white color

Tensile strength: 20-35MPa

Density: 2.12-2.20g/cm³

Hardness:50-60 Shore D

Working temperature: -180~ +260℃(short-term up to +300℃)

Chemical stability: Excellent

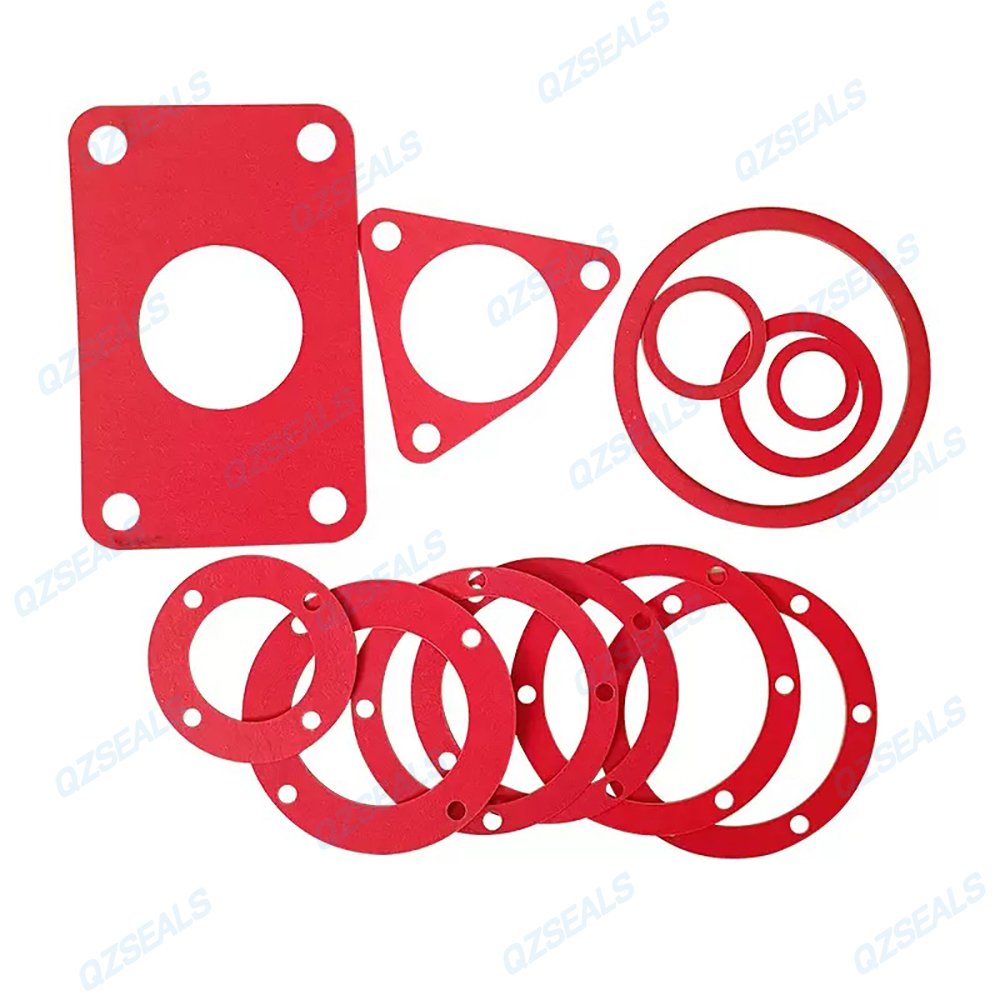

Applications: Reactors, tanks, pipelines, and valves,flanges, pressure vessels, and machinery exposed to aggressive media

Features

Exceptional chemical resistance – withstands most acids, alkalis, and solvents.

- Excellent thermal performance – stable at both high and low temperatures.

- Superior electrical insulation – maintains dielectric properties in hot and humid environments.

- Outstanding UV and weather resistance – resists light, UV radiation, and environmental aging.

- Low friction – reduces wear and enhances efficiency in dynamic applications.

- Low dielectric constant and dissipation factor – ideal for electrical and electronic applications.

- High fatigue resistance under low stress – ensures long-term performance.

- Available in food, medical, and high-purity grades – suitable for sensitive applications.

- Minimal water absorption – maintains stability in moist environments.

- Strong anti-adhesion properties – prevents sticking and material buildup.

PTFE Gasket Specification Table (mm)

| DN10 | 40*15*3 | DN15 | 45*18*3 |

| DN20 | 58*25*3 | DN25 | 68*32*3 |

| DN32 | 78*38*3 | DN40 | 88*45*3 |

| DN50 | 102*57*3 | DN65 | 122*76*3 |

| DN80 | 138*89*3 | DN100 | 158*108*3 |

| DN125 | 188*133*3 | DN150 | 212*159*3 |

| DN200 | 268*219*3 | DN250 | 322*273*3 |

| DN300 | 372*325*3 | DN350 | 438*377*3 |

| DN400 | 490*426*3 | DN450 | 532*478*3 |

| DN500 | 590*530*3 | DN600 | 690*530*3 |

| DN700 | 800*720*3 | DN800 | 900*820*3 |

| DN900 | 1000*920*3 | DN1000 | 1124*1020*3 |

Reviews

There are no reviews yet.