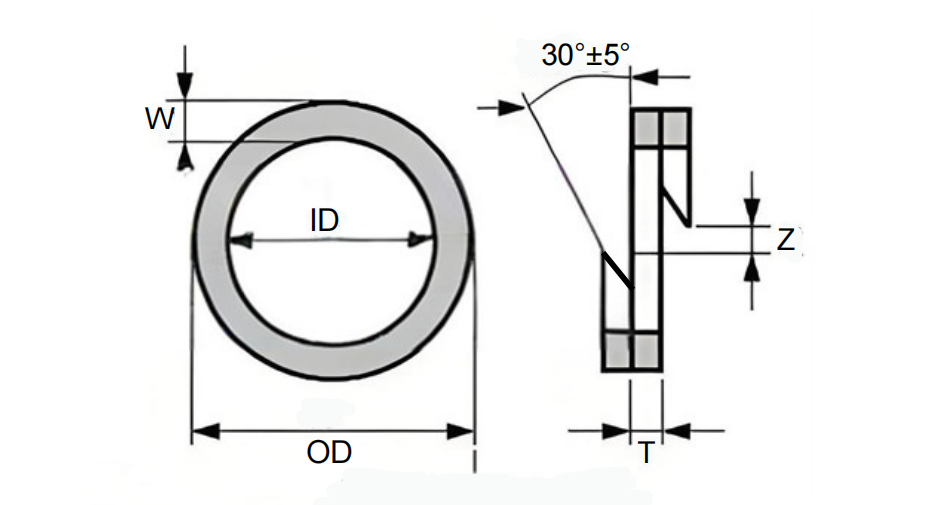

Spiral cut PTFE back up rings are made from a continuous PTFE strip wound into a multi-turn spiral shape. This design allows easy installation without excessive stretching of the O-ring and ensures good conformity to the sealing groove and mating surfaces.

Compared with solid (uncut) or single-turn scarf cut back-up rings, the spiral cut structure offers better flexibility and more uniform support to the O-ring. This reduces the risk of extrusion and improves the overall reliability of the sealing system, especially in high-pressure applications.

Technical Data

| Item | Specification |

| Material | Virgin PTFE or filled PTFE (custom compounds available) |

| Design | Multi-turn spiral cut back-up ring |

| Function | Anti-extrusion support ring for O-rings and quad rings |

| Operating Temperature | Approx. -200°C to +260°C (depending on application) |

| Chemical Resistance | Excellent resistance to most acids, bases, solvents, and gases |

| Friction Characteristics | Very low coefficient of friction, non-stick surface |

| Installation | Installed on the low-pressure side of the O-ring |

| Standard Sizes | Inch sizes according to AS568; metric sizes available |

| Customization | Special sizes, thicknesses, and materials available |

| Typical Use | High-pressure static sealing systems |

Function and Sealing Principle

O-rings provide excellent sealing performance, but under high pressure or elevated temperature they may deform and extrude into the clearance gap between mating parts, which can lead to leakage and premature seal failure.

Spiral cut PTFE back up rings are installed on the low-pressure side of the O-ring to support it and block the extrusion gap. By working together with the O-ring, the back-up ring helps maintain the seal shape under load, increases pressure capability, and significantly extends the service life of the sealing system.

Material Advantages

PTFE is widely recognized as one of the most suitable materials for back-up rings in demanding environments. It offers outstanding resistance to most chemicals, including acids, bases, solvents, and gases, and remains stable over a wide temperature range, typically from about -200°C to +260°C.

In addition, PTFE has a very low coefficient of friction and a non-stick surface, which reduces wear on the O-ring and mating parts. It does not absorb moisture, does not swell, and is not affected by aging or UV exposure, ensuring excellent long-term stability.

Types and Availability

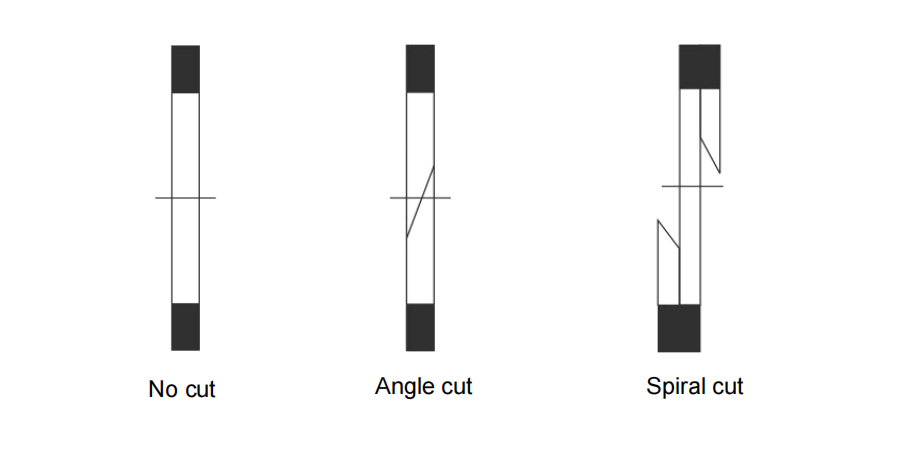

PTFE backup rings are generally available in solid (no cut), angle cut, and multi-turn spiral cut designs. Among these options, spiral cut PTFE back up rings are the most flexible and easiest to install, while still providing strong and reliable anti-extrusion support.

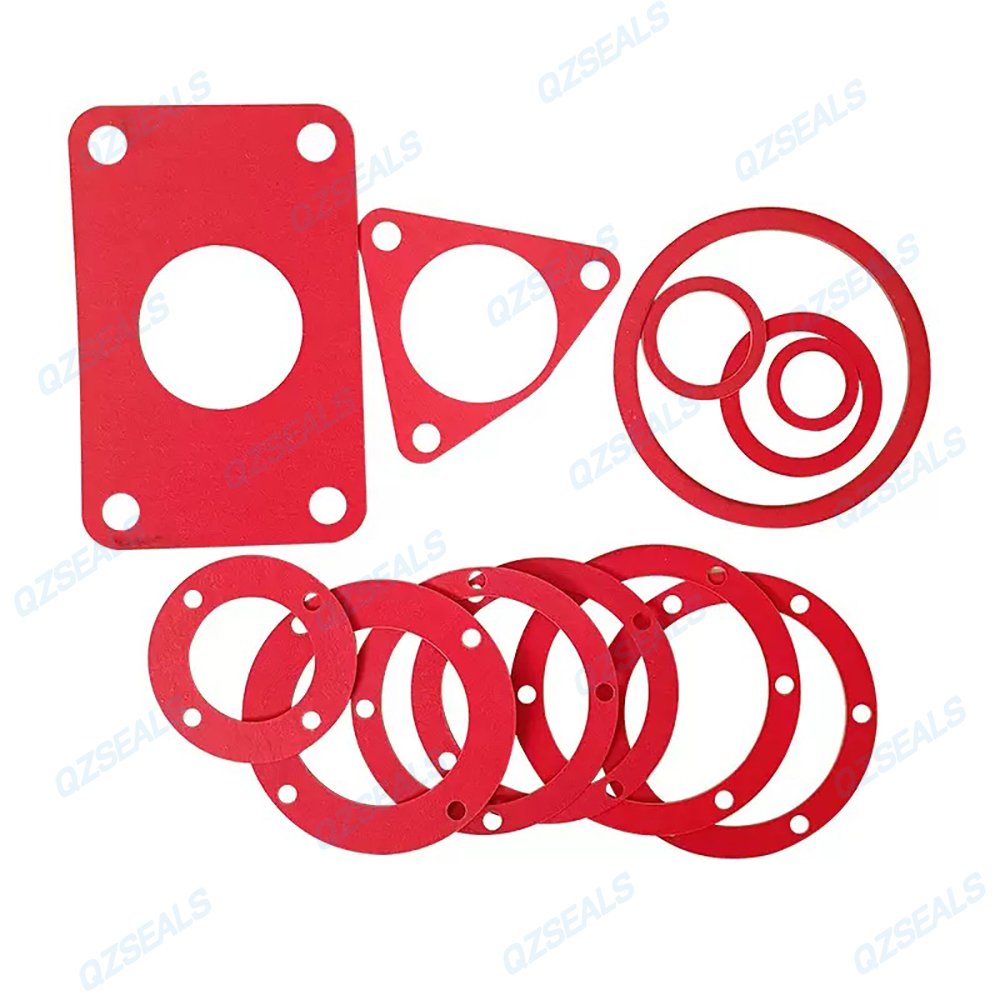

We supply both standard sizes and customized solutions, including heavy-duty and extended size versions, to meet different pressure levels, groove designs, and application requirements.

Typical Applications

Spiral cut PTFE back up rings are mainly used in static sealing systems together with O-rings or quad rings. They are widely applied in hydraulic and pneumatic cylinders, pumps, valves, and various types of industrial equipment operating under high pressure, high temperature, or aggressive media conditions.

They are especially suitable for industries such as oil and gas, chemical processing, heavy machinery, and general industrial systems where conventional elastomer seals alone are not sufficient.

Quality and Custom Solutions

QZSEALS manufactures spiral cut PTFE back up rings using advanced processing methods and strict quality control to ensure accurate dimensions and stable performance. In addition to standard products, we also provide custom solutions based on your drawings or application conditions, including special sizes, thicknesses, and PTFE compounds.

Reviews

There are no reviews yet.