Helicoil springs are manufactured by forming flat stainless steel or alloy ribbon into a continuous round-helix geometry. This design provides significantly higher load per inch of deflection compared with traditional “U” or “V” cantilever springs, making Helicoil springs ideal for static and low-speed dynamic sealing applications.

Used primarily as radial or axial compression energizers in U-Cup and similar sealing profiles, Helicoil springs deliver a very high unit load across a small deflection range and maintain reliable performance even at extremely low temperatures. The H springs are available in standard sizes, can be supplied by the foot, or cut and welded to custom diameters. Custom materials, sizes, and engineered configurations are also available to meet demanding sealing requirements.

Alternative Helcoil Springs Material

| Material | Temperature Range | Properties | Advantages |

| SS301 / 1.4310 | Up to 500°F | Good weldability; high wear & fatigue resistance | Ideal for high-elasticity springs |

| SS304 | Up to 450°F | Easy to machine; high toughness | For general industrial use |

| SS316 | Up to 400°F | Molybdenum-enhanced corrosion resistance | Works well in corrosive environments |

| C-276 | Wide range | Outstanding corrosion resistance | Suitable for harsh chemical media |

| Inconel 718 | -253°C to 700°C | High fatigue, oxidation & corrosion resistance | For high-temperature or cryogenic use |

| Elgiloy | -454°C to 800°C | Non-magnetic; excellent corrosion & fatigue strength | Best for extreme corrosive conditions |

Features

High progressive spring load – the spiral geometry delivers the highest load among all spring types.

Minimal deflection range – ensures consistent sealing performance even under low-pressure conditions.

Material versatility – standard SS301 provides excellent corrosion resistance, fatigue strength, and durability; alternative materials available for specialized applications.

- Compact design – ideal for low-pressure, vacuum, and low-temperature sealing applications.

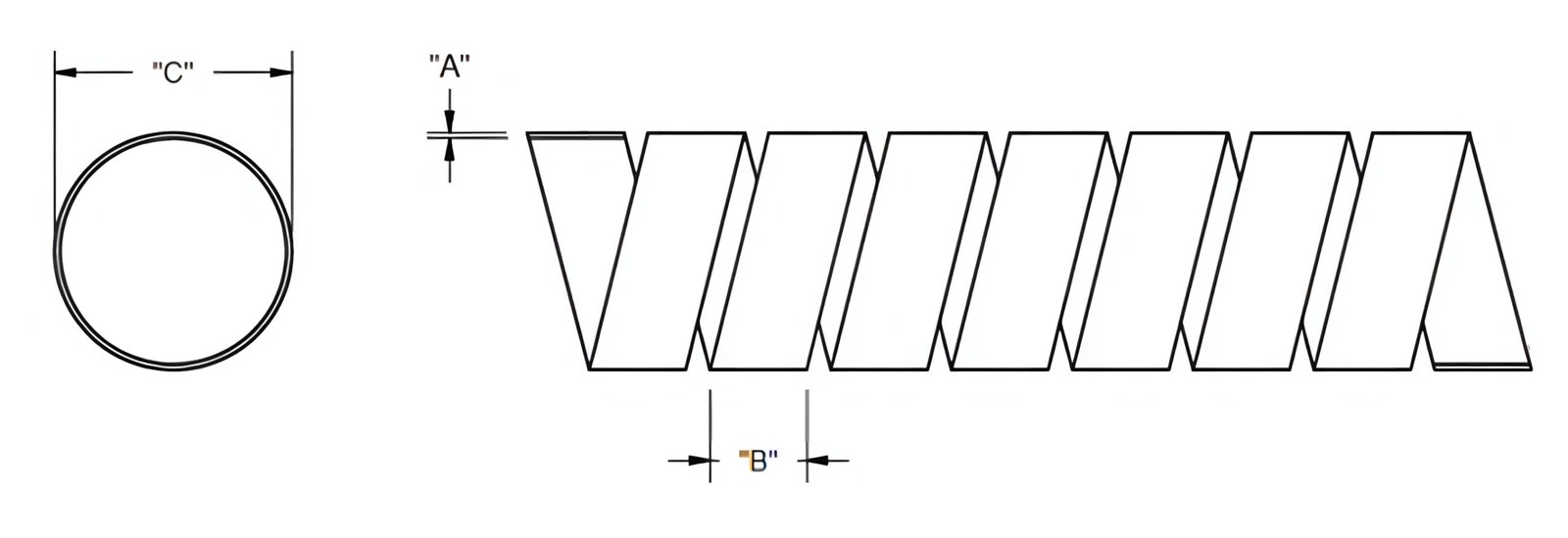

Helicoil Springs Specifications

| Size(mm) | Diameter (C) | Material Width (B) | Material thickness (A) |

| 2.0×1.5×0.1 | 2.0 | 1.5 | 0.1 |

| 2.5×1.0×0.1 | 2.5 | 1.0 | 0.1 |

| 2.5×1.5×0.1 | 2.5 | 1.5 | 0.1 |

| 2.5×2.0×0.1 | 2.5 | 2.0 | 0.1 |

| 3.0×1.0×0.1 | 3.0 | 1.0 | 0.1 |

| 3.5×1.5×0.2 | 3.5 | 1.5 | 0.2 |

| 4.0×1.5×0.15 | 4.0 | 1.5 | 0.15 |

| 4.5×1.5×0.15 | 4.5 | 1.5 | 0.15 |

| 5.0×2.0×0.15 | 5.0 | 2.0 | 0.15 |

| 5.0×2.0×0.15 | 5.0 | 2.0 | 0.15 |

| 5.5×1.5×0.15 | 5.5 | 1.5 | 0.15 |

| 6.0×2.5×0.15 | 6.0 | 2.5 | 0.15 |

| 7.0×2.5×0.15 | 7.0 | 2.5 | 0.15 |

| 7.5×2.5×0.15 | 7.5 | 2.5 | 0.15 |

| 8.0×2.5×0.15 | 8.0 | 2.5 | 0.15 |

| 9.0×3.5×0.15 | 9.0 | 3.5 | 0.15 |

| 11.7×3.5×0.25 | 11.7 | 3.5 | 0.25 |

| 15.0×4.0×0.3 | 15.0 | 4.0 | 0.3 |

| 17.0×4.0×0.3 | 17.0 | 4.0 | 0.3 |

Why Choose H springs?

- Reliable sealing performance in critical vacuum or low-pressure environments.

- Long service life due to superior fatigue resistance of stainless steel materials.

- Reduced maintenance and downtime thanks to the consistent spring load and minimal deflection.

- Customizable for your application – we can provide different materials and sizes to match your sealing requirements.

QZSEALS – Your Reliable Seal Manufacturer

At QZSEALS, we manufacture high-quality spring-energized seals and helicoil springs directly from our own production facility. Our H-type (O-type) helicoil springs are engineered in-house to deliver superior sealing reliability, long service life, and stable performance in low-pressure and vacuum applications.

Reviews

There are no reviews yet.