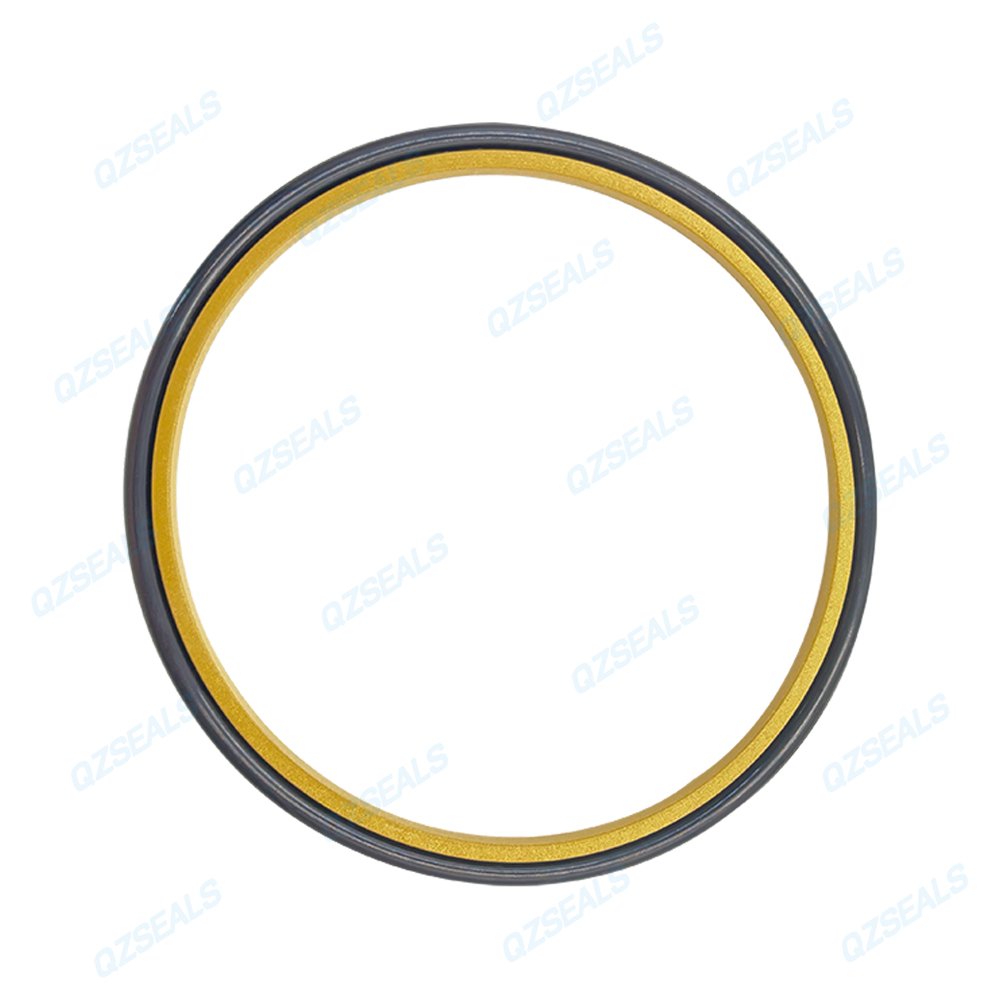

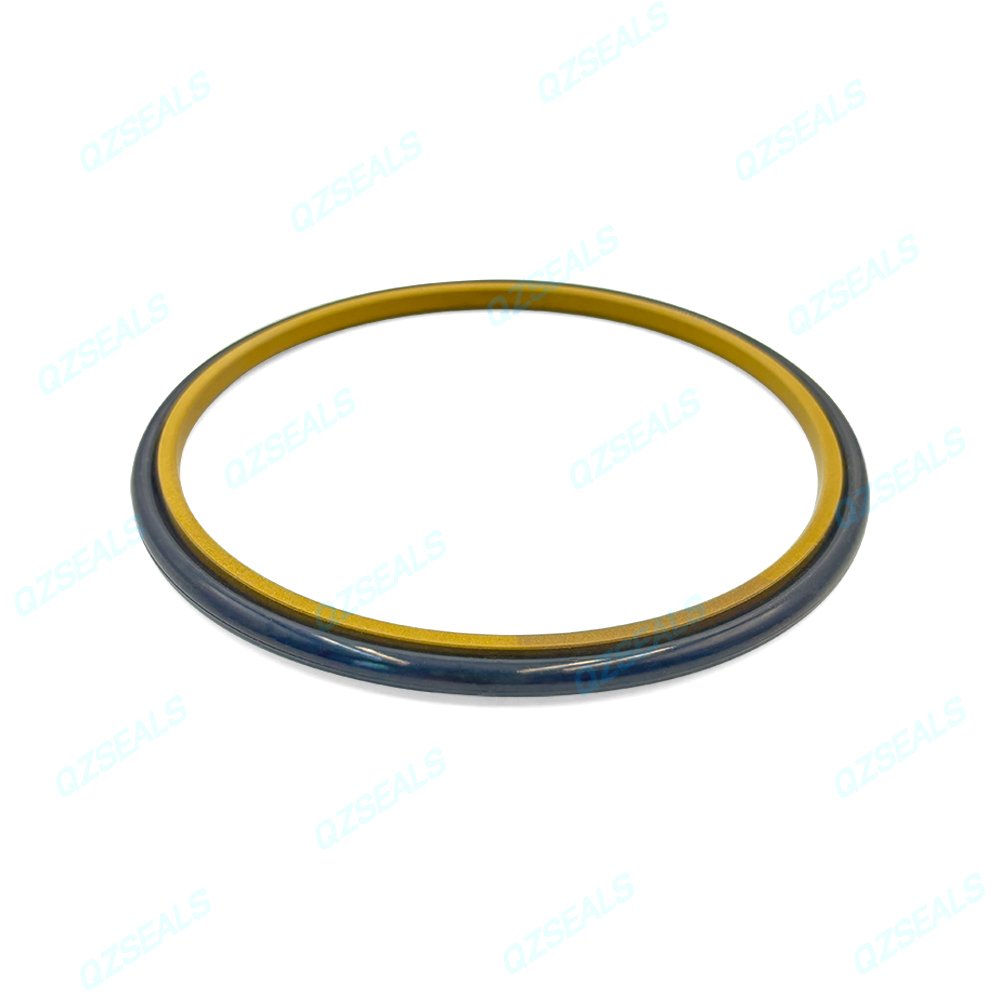

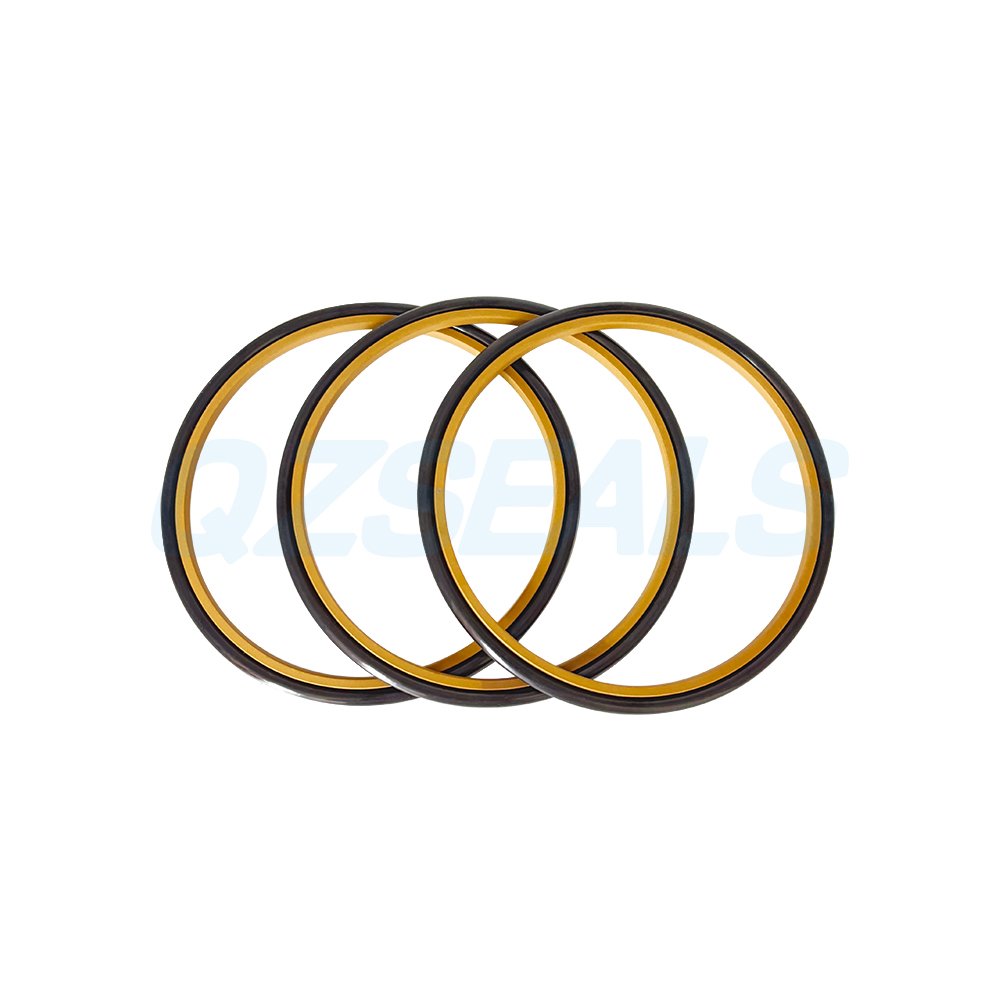

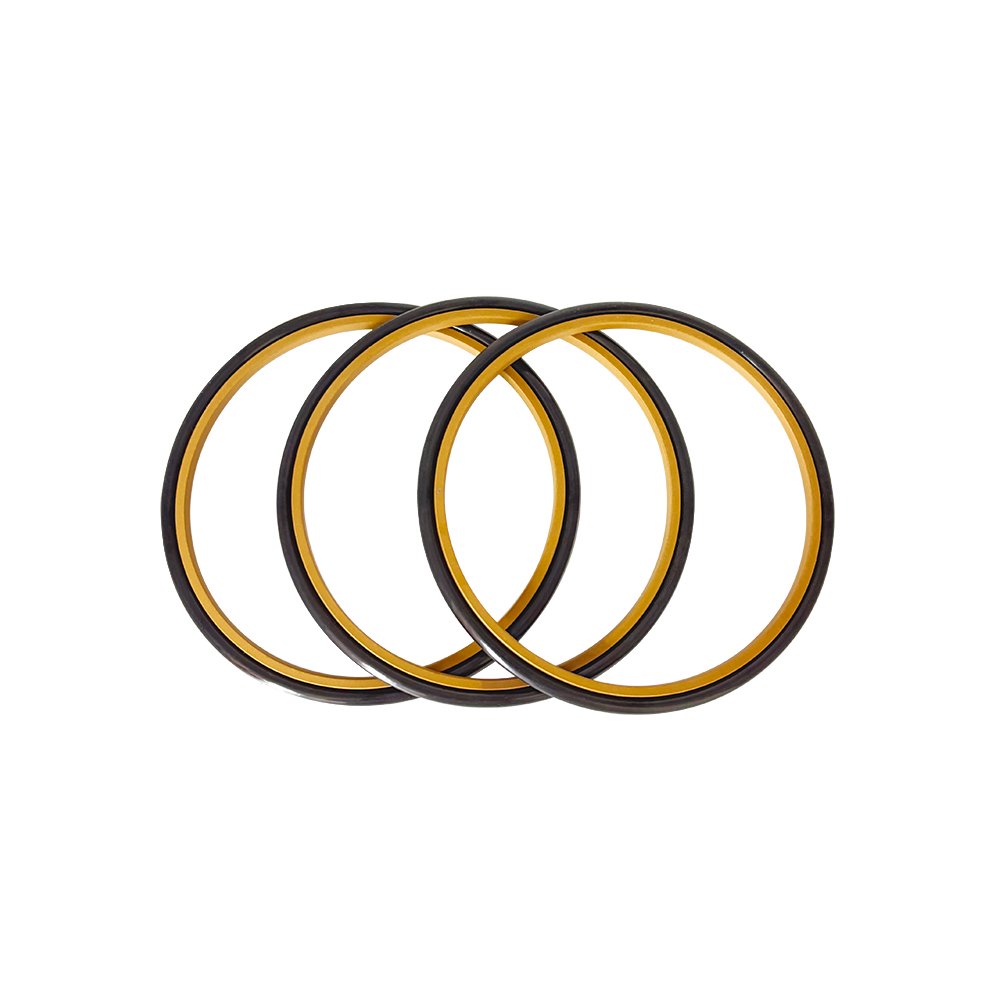

Step Seals GSJ are single-acting seals that combines a slipper sealing ring with an energizing O-Ring, commonly used as a rod seal within hydraulic sealing systems. It offers very high pressure stability under load, good thermal conductivity, excellent extrusion resistance, strong abrasion resistance, low friction, and zero stick-slip performance. Installation grooves comply with ISO 7425/2 and GB/T 15242.3 standards.

Technical Data

Pressure: ≤40 MPa

Speed: ≤15 m/s

Temperature: NBR -30~ +120℃

FKM -20~+220

Media: Fire-resistant hydraulic fluids,petroleum-based hydraulic oils, environmentally friendly biodegradable fluids (bio-oils), water

Applications: Step Seals GSJ are suitable for a wide range of strokes, diverse fluids, and high-temperature applications. Typical applications include Mobile hydraulics, excavators, forging presses, ceramic tile presses, rolling mills, Injection moulding machines, and machine tools.

Features

Dimensional stability, unaffected by temperature changes.

- Excellent dynamic and static sealing performance.

- High resistance to extrusion.

- Low friction, with no stick-slip or creeping.

- No pressure trapping; multiple seals can be installed in series.

- Superior cushioning effect against strong impact pressure

- Strong corrosion resistance.

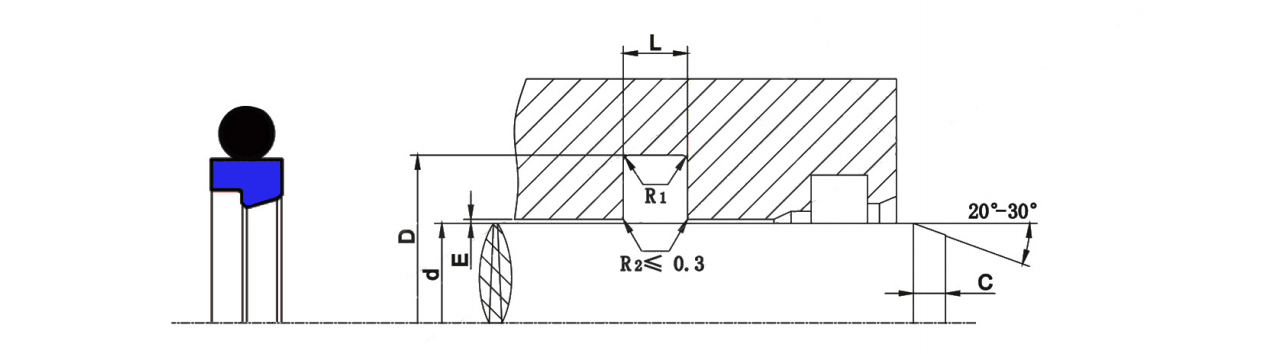

Installation Profile

Application & Installation Guidelines

- Recommended Application

Under normal working conditions, this seal is best used as a buffer seal within a hydraulic system. It is not recommended to be used as the sole sealing element.

However, if the retracting speed of the piston rod is higher than its extending speed, the seal may be used independently, but it must be paired with a double-lip dust-proof wiper for reliable performance. - O-Ring Matching Requirements

As long as the other specifications of the matched O-Ring meet the required standards, an O-Ring with an internal diameter 1–2% larger than the catalog value will still function properly and will not affect sealing performance. - Installation Method

During installation, the sealing ring may be gently folded into a heart-shaped form to place it into the groove—creases must not appear.

Among the two scenarios shown in the reference illustration, Condition A is acceptable, while Condition B must be avoided. - Installation Direction

Ensure the installation orientation is correct: the step/notch of the seal must face the direction of the oil pressure to achieve proper sealing efficiency. - Surface Hardness Requirement

For optimal performance and wear resistance, the surface hardness of the piston rod should be HRC 40 or above.

Step Seals GSJ Specification Table (mm)

| Part No. | ID(d) | OD(D) | Width(L) |

| GSJ-20 | 20 | 31 | 4.2 |

| GSJ-25 | 25 | 36 | 4.2 |

| GSJ-28 | 28 | 39 | 4.2 |

| GSJ-30 | 30 | 41 | 4.2 |

| GSJ-32 | 32 | 43 | 4.2 |

| GSJ-35 | 35 | 46 | 4.2 |

| GSJ-36 | 36 | 47 | 4.2 |

| GSJ-38 | 38 | 53.5 | 6.3 |

| GSJ-40 | 40 | 55.5 | 6.3 |

| GSJ-42 | 42 | 57.5 | 6.3 |

| GSJ-45 | 45 | 60.5 | 6.3 |

| GSJ-50 | 50 | 65.5 | 6.3 |

| GSJ-55 | 55 | 70.5 | 6.3 |

| GSJ-56 | 56 | 71.5 | 6.3 |

| GSJ-60 | 60 | 75.5 | 6.3 |

| GSJ-63 | 63 | 78.5 | 6.3 |

| GSJ-65 | 65 | 80.5 | 6.3 |

| GSJ-68 | 68 | 83.5 | 6 |

| GSJ-70 | 70 | 85.5 | 6.3 |

| GSJ-75 | 75 | 90.5 | 6.3 |

| GSJ-80 | 80 | 95.5 | 6.3 |

| GSJ-85 | 85 | 100.5 | 6.3 |

| GSJ-90 | 90 | 105.5 | 6.3 |

| GSJ-95 | 95 | 110.5 | 6.3 |

| GSJ-100 | 100 | 115.5 | 6.3 |

| GSJ-105 | 105 | 120.5 | 6.3 |

| GSJ-110 | 110 | 125.5 | 6.3 |

| GSJ-115 | 115 | 130.5 | 6.3 |

| GSJ-120 | 120 | 135.5 | 6.3 |

| GSJ-125 | 125 | 140.5 | 6.3 |

| GSJ-130 | 130 | 145.5 | 6.3 |

| GSJ-140 | 140 | 155.5 | 6.3 |

| GSJ-145 | 145 | 160.5 | 6.3 |

| GSJ-150 | 150 | 165.5 | 6.3 |

| GSJ-160 | 160 | 175.5 | 6.3 |

Reviews

There are no reviews yet.