Technical Data

- Pressure: ≤0.3bar

- Temperature: NBR -30~ +120℃, FKM -20~+220℃

- Media: Grease, oil, water

- Applications: Used on rotating shaft ends of equipment to seal fluids and lubricants under pressure differences up to 0.03 MPa.

TC oil Seal material options

Nitrile Rubber (NBR):

Good heat and wear resistance, compatible with most lubricating oils, greases, and oil-gas mixtures. Suitable for -30°C to +120°C. Not recommended for phosphate ester hydraulic oils or gear oils with extreme pressure additives. Stable in gasoline and low-aniline-point mineral oils.

FKM / Viton:

Excellent aging, heat, and oil resistance. Works with most lubricants, fuels, and gasoline. Poor cold resistance, high-temperature wear, and some permanent compression deformation. Suitable for -20°C to +220°C.

FFKM / Perfluoroether:

Outstanding chemical, heat, and oxidation resistance. Compatible with aggressive chemicals, high temperatures, and extreme operating conditions. Suitable for -20°C to +300°C.

Silicone:

Exceptional high and low-temperature performance. Can operate continuously at +150°C and up to 10,000 hours at 200°C, maintaining elasticity and ozone resistance. Suitable for -70°C to +260°C.

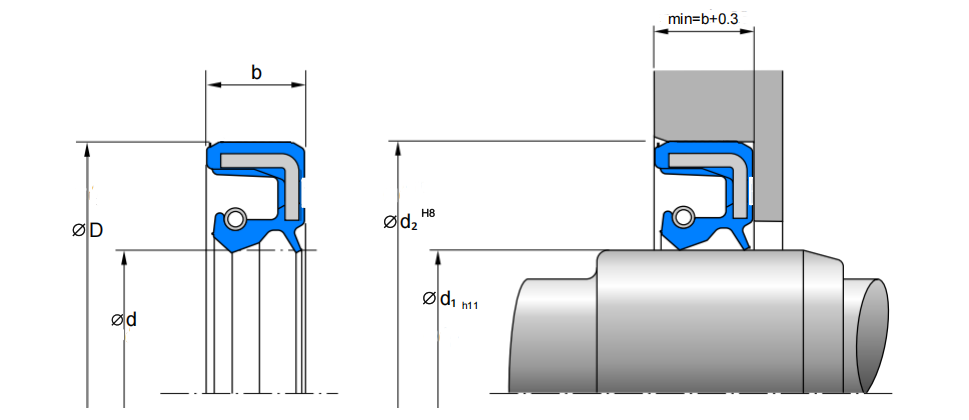

Features

- Low-friction dual-lip design

- Garter spring ensures consistent sealing pressure

- Rubber-covered OD for enhanced sealing

- Dust lip protects primary sealing lip

- Durable construction suitable for polluted environments

Installation Profile

Interference Fit Between Oil Seal Outer Diameter and Housing Bore (Interference Amount) Unit:mm

| Outer Diameter Range (D, mm) | Interference (Metal Case) | Interference (Rubber Covered) | Outer Diameter Tolerance (Metal Case) | Outer Diameter Tolerance (Rubber Covered) |

| D ≤ 50 | +0.20/+0.08 | +0.30/+0.15 | 0.18 | 0.25 |

| 50 < D ≤ 80 | +0.23/+0.09 | +0.35/+0.20 | 0.25 | 0.35 |

| 80 < D ≤ 120 | +0.25/+0.10 | +0.35/+0.20 | 0.30 | 0.50 |

| 120 < D ≤ 180 | +0.28/+0.12 | +0.45/+0.25 | 0.40 | 0.65 |

| 180 < D ≤ 300 | +0.35/+0.15 | +0.45/+0.25 | 0.25% of OD | 0.80 |

| 300 < D ≤ 440 | +0.45/+0.20 | +0.55/+0.30 | 0.25% of OD | 1.00 |

Interference Fit Between Oil Seal Inner Diameter and Shaft Outer Diameter (Interference Amount) Unit:mm

| Shaft Diameter Range (mm) | Interference (Main Lip) | Limit Deviation (Main Lip) | Interference (Auxiliary Lip) | Limit Deviation (Auxiliary Lip) |

| 5~30 | 0.7~1.0 | +0.2/-0.3 | 0.3 | ±0.15 |

| 30~60 | 1.0~1.2 | +0.2/-0.5 | 0.4 | ±0.20 |

| 60~80 | 1.2~1.4 | +0.2/-0.6 | 0.5 | ±0.25 |

| 80~130 | 1.4~1.8 | +0.2/-0.8 | 0.6 | ±0.30 |

| 130~250 | 1.8~2.4 | +0.2/-0.9 | 0.7 | ±0.35 |

| 250~400 | 2.4~3.0 | +0.2/-1.0 | 0.9 | ±0.40 |

Usage Precautions

- Match seal type to shaft speed: high-speed shafts → high-speed seals; low-speed shafts → low-speed seals.

- Select material based on operating temperature: silicone, fluororubber, or perfluoroether (FFKM) for high temps; cold-resistant rubber for low temps.

- For high-pressure conditions, use reinforced seals or support rings.

- Minimize shaft eccentricity and maintain smooth shaft surfaces.

- Keep sealing lips properly lubricated.

- Prevent dust or contaminants from entering the seal.

Reviews

There are no reviews yet.