VS ring flexible lip compensates for shaft misalignment and tolerance variations, preventing oil or grease leakage and blocking dust and water ingress. Ideal for V-ring seal applications in both OEM and replacement use.

VS Ring Material Options

VS ring is typically manufactured from high-performance elastomers to meet various application requirements. The most common materials include Nitrile Rubber (NBR) and Fluoroelastomer (FKM/Viton), both offering excellent sealing performance and durability. The standard hardness for these rubbers is around 60 Shore A, ensuring reliable flexibility and wear resistance. Other materials such as silicone,HNBR and EPDM are available for special working conditions.

NBR (Nitrile Rubber) – Offers excellent oil resistance and good elasticity, ideal for sealing in contact with mineral oils, greases, and hydraulic fluids. Typical working temperature range: -40°C to +100°C. Widely used in automotive seals, bearings, pumps, and V-ring water seals (e.g., VA and VL types).

FKM (Viton) – Provides superior heat and chemical resistance, capable of withstanding up to +200°C. Suitable for use with synthetic oils, acids, and alkaline media, making it ideal for high-temperature or chemically aggressive environments.

Silicone Rubber (VMQ) – Known for its exceptional flexibility and thermal stability, maintaining elasticity from -60°C to +200°C. Ideal for food-grade, medical, or outdoor applications requiring long-term sealing performance under temperature variation.

HNBR (Hydrogenated Nitrile Rubber) – A hydrogenated version of NBR with enhanced temperature and oxidation resistance. Operates between -40°C and +150°C, while maintaining excellent oil resistance. Commonly used in chemical processing and high-temperature hydraulic systems.

EPDM (Ethylene Propylene Diene Rubber) – Exhibits outstanding resistance to water, steam, and weathering, suitable for non-oil media such as water and air. Typically used in water treatment systems, humid environments, and outdoor sealing applications.

Technical Data

Pressure: ≤40MPa

Speed: ≤19m/s

Temperature:-40℃~+200℃(depending on material)

Medium: mineral oil, air, water, emulsion, grease.

Features

- Requires minimal design work with no special installation or machining needed.

- Eliminates the need for surface finish or shaft hardness requirements.

- Mating surfaces do not need to be hardened.

- No shaft wear occurs.

- Provides both sealing and contamination protection functions.

- Suitable for high-speed applications

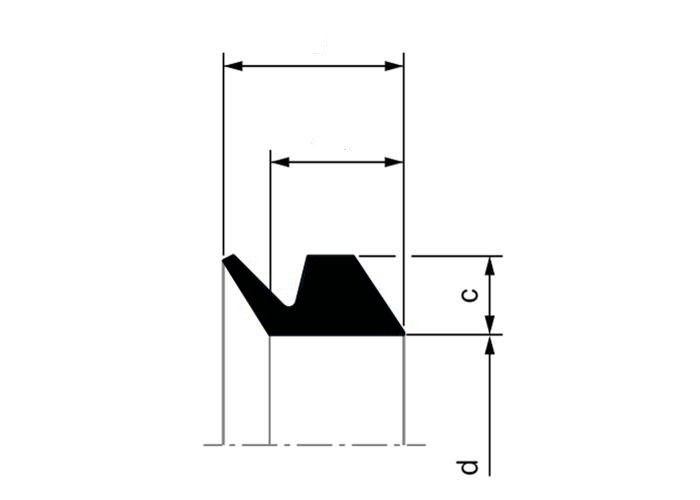

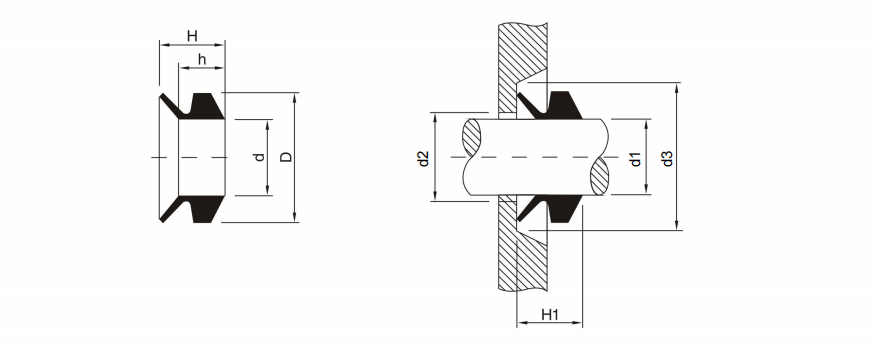

Installation Profile

VS Ring Specification Table (mm)

| Name | ID | OD | Height | Shaft Diameter | Size | Wall Thickness | Maximum | Minimum |

| Ref. | d | D | H | d1 | h | c | d2 | d3 |

| VS-5 | 4 | 8 | 5.2 | 4.5-5.5 | 3.9 | 2 | d1+1 | d1+6 |

| VS-6 | 5 | 9 | 5.2 | 5.5-6.5 | 3.9 | 2 | d1+1 | d1+6 |

| VS-7 | 6 | 10 | 5.2 | 6.5-8.0 | 3.9 | 2 | d1+1 | d1+6 |

| VS-8 | 7 | 11 | 5.2 | 8.0-9.5 | 3.9 | 2 | d1+1 | d1+6 |

| VS-10 | 9 | 15 | 7.7 | 9.5-11.5 | 5.6 | 3 | d1+1 | d1+9 |

| VS-12 | 10.5 | 16.5 | 7.7 | 11.5-13.5 | 5.6 | 3 | d1+1 | d1+9 |

| VS-14 | 12.5 | 18.5 | 7.7 | 13.5-15.5 | 5.6 | 3 | d1+1 | d1+9 |

| VS-16 | 14 | 20 | 7.7 | 15.5-17.5 | 5.6 | 3 | d1+1 | d1+9 |

| VS-18 | 16 | 22 | 7.7 | 17.5-19 | 5.6 | 3 | d1+1 | d1+9 |

| VS-20 | 18 | 26 | 10.5 | 19-21 | 7.9 | 4 | d1+2 | d1+12 |

| VS-22 | 20 | 28 | 10.5 | 21-24 | 7.9 | 4 | d1+2 | d1+12 |

| VS-25 | 22 | 30 | 10.5 | 24-27 | 7.9 | 4 | d1+2 | d1+12 |

| VS-28 | 25 | 33 | 10.5 | 27-29 | 7.9 | 4 | d1+2 | d1+12 |

| VS-30 | 27 | 35 | 10.5 | 29-31 | 7.9 | 4 | d1+2 | d1+12 |

| VS-32 | 29 | 37 | 10.5 | 31-33 | 7.9 | 4 | d1+2 | d1+12 |

| VS-35 | 31 | 39 | 10.5 | 33-36 | 7.9 | 4 | d1+2 | d1+12 |

| VS-38 | 34 | 42 | 10.5 | 36-38 | 7.9 | 4 | d1+2 | d1+12 |

| VS-40 | 36 | 46 | 13 | 38-43 | 9.5 | 5 | d1+2 | d1+15 |

| VS-45 | 40 | 50 | 13 | 43-48 | 9.5 | 5 | d1+2 | d1+15 |

| VS-50 | 45 | 55 | 13 | 48-53 | 9.5 | 5 | d1+2 | d1+15 |

| VS-55 | 49 | 59 | 13 | 53-58 | 9.5 | 5 | d1+2 | d1+15 |

| VS-60 | 54 | 64 | 13 | 58-63 | 9.5 | 5 | d1+2 | d1+15 |

| VS-65 | 58 | 68 | 13 | 63-68 | 9.5 | 5 | d1+2 | d1+15 |

| VS-70 | 63 | 75 | 15.5 | 68-73 | 11.3 | 6 | d1+3 | d1+18 |

| VS-75 | 67 | 79 | 15.5 | 73-78 | 11.3 | 6 | d1+3 | d1+18 |

| VS-80 | 72 | 84 | 15.5 | 78-83 | 11.3 | 6 | d1+3 | d1+18 |

| VS-85 | 76 | 88 | 15.5 | 83-88 | 11.3 | 6 | d1+3 | d1+18 |

| VS-90 | 81 | 93 | 15.5 | 88-93 | 11.3 | 6 | d1+3 | d1+18 |

| VS-95 | 85 | 97 | 15.5 | 93-98 | 11.3 | 6 | d1+3 | d1+18 |

| VS-100 | 90 | 102 | 15.5 | 98-105 | 11.3 | 6 | d1+3 | d1+18 |

| VS-110 | 99 | 113 | 18 | 105-115 | 13.1 | 7 | d1+4 | d1+21 |

| VS-120 | 108 | 122 | 18 | 115-125 | 13.1 | 7 | d1+4 | d1+21 |

| VS-130 | 117 | 131 | 18 | 125-135 | 13.1 | 7 | d1+4 | d1+21 |

| VS-140 | 126 | 140 | 18 | 135-145 | 13.1 | 7 | d1+4 | d1+21 |

| VS-150 | 135 | 149 | 18 | 145-155 | 13.1 | 7 | d1+4 | d1+21 |

| VS-160 | 144 | 160 | 20.5 | 155-165 | 15 | 8 | d1+4 | d1+24 |

| VS-170 | 153 | 169 | 20.5 | 165-175 | 15 | 8 | d1+4 | d1+24 |

| VS-180 | 162 | 178 | 20.5 | 175-185 | 15 | 8 | d1+4 | d1+24 |

| VS-190 | 171 | 187 | 20.5 | 185-195 | 15 | 8 | d1+4 | d1+24 |

| VS-199 | 180 | 196 | 20.5 | 195-210 | 15 | 8 | d1+4 | d1+24 |

Reviews

There are no reviews yet.