Z8 pneumatic seals are single-acting, non-symmetrical pneumatic piston seal designed with a short, thin dynamic lip to ensure low friction and reliable sealing in air cylinders.

Technical Data

Material: NBR 80 shore A

Pressure: ≤1.6 MPa

Speed: ≤ 1 m/s

Temperature: -30~ +120℃

Medium: Lubricated air, dry air, or oil-free air (initial lubrication required during assembly.

Applications: pneumatic cylinders, air valves, automation equipment, industrial machinery.

Features

Excellent sealing performance even with small groove dimensions.

- Low static and dynamic friction for smooth motion.

- Compact design – suitable for modern pneumatic systems.

- Good wear resistance and long service life.

- Easy to install on piston and in groove.

- Stable operation due to optimal lip geometry that retains lubricant

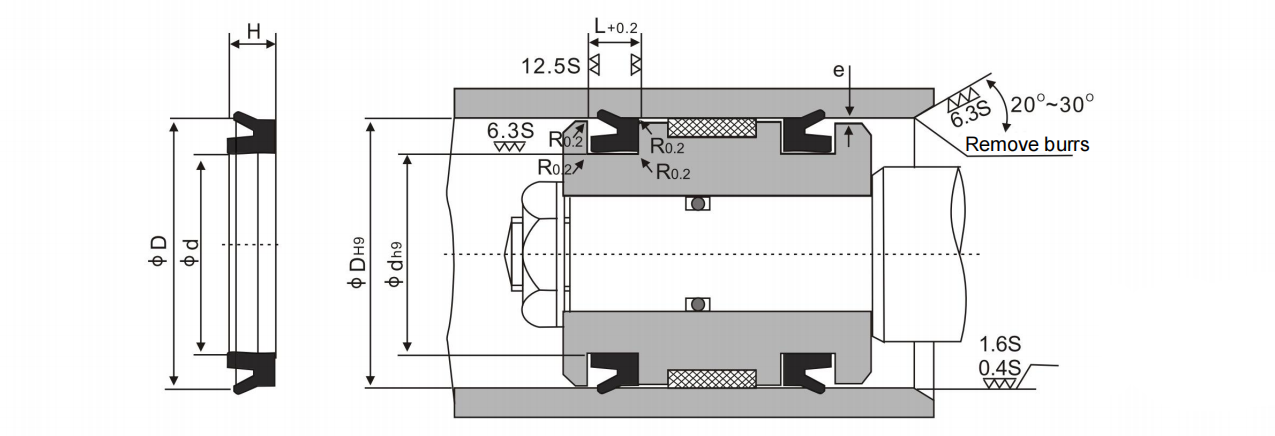

Installation Profile

Installation Tips

Z8 pneumatic seals can be easily fitted over the piston into the groove.

⚠️ Avoid sharp edges during installation to prevent lip damage.

In oil-free systems, make sure the seal surface is properly lubricated before assembly to extend service life.

Specification Table (mm)

| Name | D | d | H |

| Z8-4 | 4 | 1.5 | 1.5 |

| Z8-5 | 5 | 2.5 | 1.5 |

| Z8-6 | 6 | 3 | 2 |

| Z8-8 | 8 | 4 | 2.55 |

| Z8-10 | 10 | 3 | 3.5 |

| Z8-12 | 12 | 7 | 2.55 |

| Z8-13 | 13 | 8 | 2.55 |

| Z8-14 | 14 | 8 | 2.55 |

| Z8-15 | 15 | 9 | 2.55 |

| Z8-16 | 16 | 10 | 2.55 |

| Z8-18 | 18 | 12 | 3.25 |

| Z8-20 | 20 | 14 | 2.55 |

| Z8-21 | 21 | 15 | 2.55 |

| Z8-22 | 22 | 16 | 2.55 |

| Z8-24 | 24 | 18 | 3.25 |

| Z8-25 | 25 | 19 | 3.25 |

| Z8-28 | 28 | 22 | 3.25 |

| Z8-30 | 30 | 22 | 3.25 |

| Z8-32 | 32 | 24 | 3.25 |

| Z8-35 | 35 | 27 | 3.25 |

| Z8-36 | 36 | 28 | 3.25 |

| Z8-37 | 37 | 29 | 3.25 |

| Z8-38 | 38 | 30 | 3.25 |

| Z8-40 | 40 | 32 | 3.25 |

| Z8-42 | 42 | 34 | 3.25 |

| Z8-44 | 44 | 52 | 4.6 |

| Z8-45 | 45 | 37 | 3.25 |

Customization

At QZSEALS, we specialize in custom-made pneumatic seals. surface is properly lubricated before assembly to extend service life.

We can produce Z8 piston seals according to your drawings, samples, or special material requirements.

Our professional sealing engineers ensure performance and durability even in demanding conditions.

Why Choose QZSEALS

- Over 15 years of sealing expertise.

- Wide material options: NBR, FKM, PU, PTFE, EPDM, and more.

- ISO-compliant quality control.

- Fast global delivery & reliable after-sales support.

- OEM / ODM custom seal manufacturing service.

Reviews

There are no reviews yet.