Abstract

In high-speed rolling mills, gearbox and bearing failures cause serious production losses and high maintenance costs. Based on long-term industrial practice in wire rod rolling mills, this article analyzes typical failure modes of rolling mill gearboxes, with special focus on frequent oil film bearing burnout. The study shows that water contamination of the lubrication system is the fundamental cause of oil degradation and bearing damage.

Furthermore, this article explains the formation mechanism of sludge and gel-like deposits in lubricating oil, evaluates the influence of water on oil film thickness, and highlights the critical role of the rolling mill double lip seal in preventing water ingress. Finally, systematic preventive measures are proposed to improve gearbox reliability, extend service life, and reduce unplanned downtime in rolling mill operations.

1. Introduction

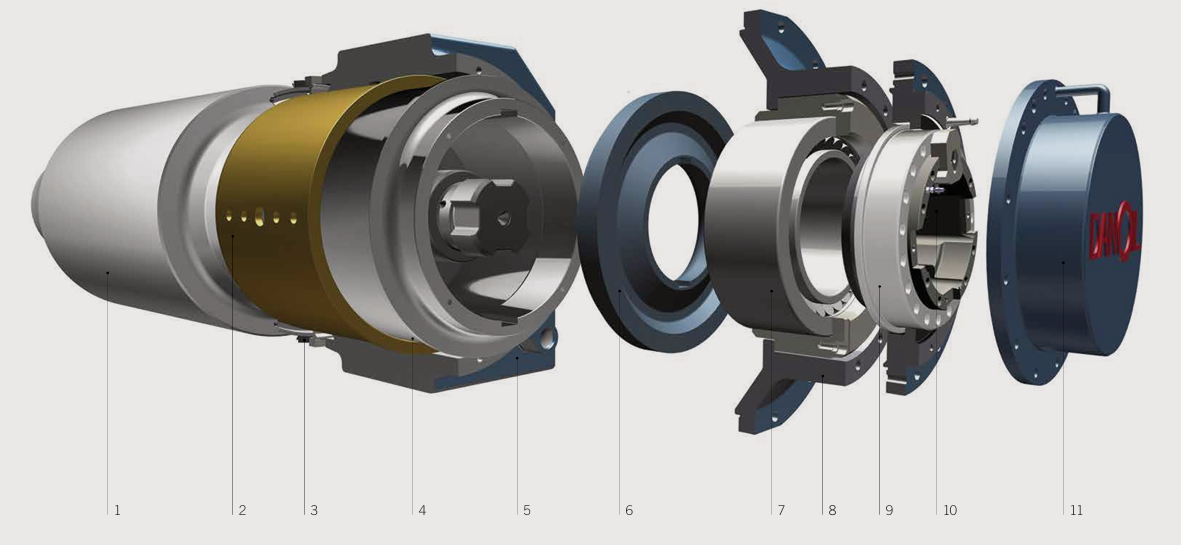

In modern high-speed rolling mills, especially wire rod finishing mills, the core equipment is required to operate under extremely severe conditions, including high speed, heavy load, strong vibration, high temperature, and intensive cooling water spray. In many production lines, the pre-finishing and finishing mill stands, as well as key gearbox and drive systems, are supplied by internationally recognized rolling mill equipment manufacturers such as Danieli, whose technologies are widely used in high-speed long product and wire rod mills. Under such demanding operating conditions, the stability of the lubrication system and the reliability of the sealing system become decisive factors for the service life of rolling mill gearboxes and bearings.

In practical operation, it is observed that bearing burnout and gearbox damage occur much more frequently than expected. These failures not only increase maintenance costs but also seriously affect production stability. Therefore, a systematic analysis of failure modes and their root causes is essential for improving the reliability of rolling mill equipment.

2. Failure Modes and Cause Analysis of Rolling Mill Gearboxes

2.1 Causes of Roll Gap Adjustment Screw Failure

The roll gap adjustment mechanism is frequently operated during production to maintain product dimensional accuracy. If the supporting structure of the adjustment screw lacks sufficient strength, long-term cyclic loading and frequent adjustment can lead to fatigue cracking and eventual fracture. Once the support fails, the screw is subjected to abnormal bending and torsional stress, which accelerates its failure.

In engineering practice, reinforcing the support structure and improving the stiffness of the mounting base can effectively eliminate this type of mechanical failure. Although this problem is mainly structural, it highlights the importance of mechanical rigidity in high-speed rolling mill equipment.

2.2 Causes of Shaft Shoulder and Spline Damage

Damage to shaft shoulders and splines is usually related to assembly quality and tightening force. In many cases, small metal particles or contaminants remain between the roll ring, taper sleeve, and shaft during assembly. These contaminants prevent proper surface contact and reduce the actual clamping force.

In addition, if the hydraulic tightening force does not reach the specified value, the roll ring may not be fully secured. Under high-speed rotation, micro-movement occurs between mating surfaces. This relative movement causes fretting wear between the roll ring and taper sleeve, between the taper sleeve and shaft, and between the oil slinger and shaft splines. Over time, this leads to serious wear of the shaft shoulder and damage to the splines.

By establishing strict assembly procedures, improving cleanliness control, and rechecking the tightening force after a short period of operation, this type of failure can be significantly reduced.

2.3 Causes of Oil Film Bearing Burnout

When the operating temperature of an oil film bearing exceeds safe limits, the bearing must be replaced. Analysis of failed bearings and shafts often shows a thin layer of brown, sticky deposits on the bearing surfaces and shaft journals. At the same time, abnormal substances such as white solid particles and dark brown gel-like materials are frequently found in the lubrication oil tank.

Comparative analysis indicates that the sticky deposits on the shaft surface and the gel-like substances separated from the oil belong to the same type of material. This proves that the fundamental cause of bearing burnout is long-term water contamination of the lubrication system, which leads to oil degradation and the formation of harmful deposits.

Oil analysis further confirms that the white solid particles are mainly water-soluble alkaline substances introduced by water ingress. As water is separated from the oil, these alkaline compounds precipitate and cause corrosive damage to metal surfaces.

2.3.1 Main Components of the Gel-Like Deposits

The gel-like deposits are mainly composed of asphaltenes, resins, and polycyclic aromatic compounds. These substances have limited solubility in lubricating oil and usually exist in the form of colloidal macromolecules. Because they are partially dissolved in the oil, conventional filters cannot effectively remove them from the lubrication system.

2.3.2 Formation Mechanism of the Gel-Like Deposits

The formation of these deposits is closely related to oil degradation caused by water contamination.

First, long-term water ingress leads to oil emulsification, hydrolysis of additives, and an increase in dissolved oxygen content. This accelerates oil oxidation and the corrosive effect of organic acids on metal surfaces, resulting in a higher carbon residue and poorer low-temperature fluidity.

Second, in many rolling mill lubrication systems, there is no standby oil tank. As a result, the oil does not have sufficient resting time to recover additive stability or to allow water and contaminants to settle and separate. In addition, purification equipment often needs to operate continuously due to high water content, subjecting the oil to long-term thermal stress and mechanical agitation, which further accelerates oxidation and viscosity degradation.

Third, according to elastohydrodynamic lubrication theory, the minimum oil film thickness required for bearing operation depends strongly on oil viscosity and density. When water enters the oil, the effective viscosity decreases, leading to a thinner oil film. Once the oil film becomes too thin, it can no longer separate the bearing surfaces, and overheating and burnout occur.

3. Influence of Water Contamination on Rolling Mill Bearing Failure

In oil film bearings of rolling mills, the shaft rotates at very high speed and is subjected to centrifugal force and elevated temperature. When degraded oil containing gel-like macromolecules is present, these soft deposits gradually accumulate on the shaft surface. This accumulation destroys the formation of a stable oil film.

As a result, the bearing shell and shaft begin to experience direct contact and dry friction. The bearing surface is subjected to high stress, leading to surface fatigue, peeling, and removal of the Babbitt layer. The bearing temperature rises rapidly, and eventually, bearing burnout occurs.

From practical experience, it can be concluded that water ingress into the oil tank is the primary root cause of rolling mill gearbox bearing failure. Therefore, strict control of water contamination is essential. The operating time with excessive water content must be minimized, and long-term operation with contaminated oil should be strictly avoided.

4. Main Sources of Water Ingress in Rolling Mill Gearboxes

4.1 Leakage in Heat Exchangers

In some cases, internal leakage in plate-type heat exchangers can cause cooling water to enter the lubrication oil system. Pressure testing and regular inspection are necessary to exclude this possibility and ensure the integrity of the heat exchanger.

4.2 Seal Failure Between Gearbox Housings

Poor sealing between different gearbox housings, such as between the bevel gear box and the roll box, can also lead to water ingress. Although the mating surfaces are usually precision-machined and sealed with sealant, improper seal size, incorrect installation, or damaged O-rings can still result in leakage. Proper control of seal interference and compression ratio is critical to maintaining sealing performance.

5. Main Causes of Water Ingress into the Oil Tank

5.1 Water Ingress at Shaft Double Lip Seals

In practice, the most common and most critical source of water ingress is the shaft sealing area. The rolling mill double lip seal must simultaneously exclude external water and retain internal oil. If this seal fails, water can easily enter the lubrication system and contaminate the entire oil tank.

5.2 Typical Failure Modes of Double Lip Seals

First, the sealing lips are the actual contact surfaces with the oil slinger rings. If the wear of the lip reaches a critical level, the contact pressure decreases and the sealing function is lost, allowing water to pass through.

Second, seal aging is another important factor. Under the combined effects of high temperature, impact, water immersion, and air purge pressure, rubber materials gradually lose elasticity, become brittle, and crack, which accelerates wear and deformation.

Third, assembly quality directly affects sealing performance. Misalignment, contamination during installation, or uneven compression can all cause premature seal failure.

Fourth, the quality and material selection of the seal itself are crucial. Differences in material, hardness, and dimensional accuracy influence the pressure distribution at the lip edge. If the contact pressure is too low, sealing will be ineffective; if it is too high, wear will increase and service life will be shortened.

Finally, the air purge system must be properly controlled. If the air pressure is too low, it cannot effectively support the sealing lip. If it is too high, it may damage the seal or accelerate wear. In addition, moist or contaminated compressed air can block air passages and introduce more contaminants into the sealing area.

6. Preventive Measures for Improving Rolling Mill Gearbox Reliability

6.1 Regular Replacement and Maintenance of Gearboxes

Rolling mill gearboxes should be taken out of service at fixed intervals for inspection, cleaning, and maintenance. This preventive approach can identify potential problems before they develop into serious failures.

6.2 Regular Replacement of Double Lip Seals

Different mill stands may have different operating conditions, so seal replacement intervals should be determined based on actual wear and environmental severity. Regular replacement of rolling mill double lip seal is one of the most effective ways to prevent water ingress.

6.3 Optimization of Seal Materials and Design

Close cooperation with seal manufacturers can help improve material selection and structural design. By enhancing wear resistance, high-temperature performance, and resistance to compression set, the service life and reliability of the seal can be significantly improved.

6.4 Strict Control of Installation Quality

During seal replacement, it is essential to ensure that all components are clean, the supporting parts are flat and parallel, and the compression of the sealing lips is within the specified range. Uneven compression can lead to localized overheating or leakage and must be avoided.

6.5 Improvement of Air Purge System Quality

Installing proper air filtration, drying, and lubrication units can greatly improve the cleanliness and reliability of the air purge system. The air pressure should be maintained within a suitable range to balance sealing performance and wear rate.

6.6 Continuous Monitoring and Purification of Lubrication Oil

Regular oil analysis should be carried out to monitor cleanliness and water content. When contamination is detected, centrifugal separators or vacuum oil purifiers should be put into operation immediately to remove water and solid particles. Maintaining the oil level within an optimal range also helps improve degassing and sedimentation performance.

7. Conclusion

Practical experience in high-speed rolling mills proves that frequent gearbox bearing burnout is not merely a bearing problem, but a systematic issue closely related to lubrication quality and sealing reliability. Water contamination of lubricating oil is the fundamental root cause of oil degradation, sludge formation, oil film breakdown, and ultimately catastrophic bearing failure. Once water enters the system, even the best bearings and gears cannot maintain stable operation for long periods.

In this context, the rolling mill double lip seal is not just a standard spare part, but a critical reliability component that forms the first and most important barrier against water ingress and oil leakage. High-quality seal design, correct material selection, and strict installation control are essential for maintaining long-term stability of the lubrication system.

At QZSEALS, we focus on engineering-grade sealing solutions for harsh industrial environments such as rolling mills. Our rolling mill double lip seal is designed with optimized lip geometry and carefully selected compounds to balance sealing performance, wear resistance, and service life under high speed, high temperature, and water-rich conditions. Combined with proper installation and disciplined maintenance, these sealing solutions help steel plants significantly reduce water contamination risks, stabilize oil condition, and extend the service life of gearboxes and bearings.

By integrating reliable sealing products from QZSEALS with systematic lubrication management and condition monitoring, rolling mill operators can move from reactive maintenance to preventive reliability control—reducing unplanned downtime, lowering total maintenance costs, and achieving more stable and predictable production in modern rolling mill operations.