Introduction: The Genesis of the Problem-Solver Seal

In the hierarchy of sealing technologies, standard elastomeric O-rings and lip seals represent the foundation—reliable, cost-effective, and suitable for a vast majority of conventional industrial sealing applications. However, as engineering frontiers are pushed, a class of applications emerges where the operational demands of temperature, pressure, speed, and chemical aggression create conditions that would cause any standard elastomer to fail catastrophically. In the cryogenic depths of aerospace fuel systems, the searing heat of gas turbines, the high-pressure environment of oil and gas equipment, or the aggressive chemical reactors of the processing industry, a different kind of sealing solution is required.

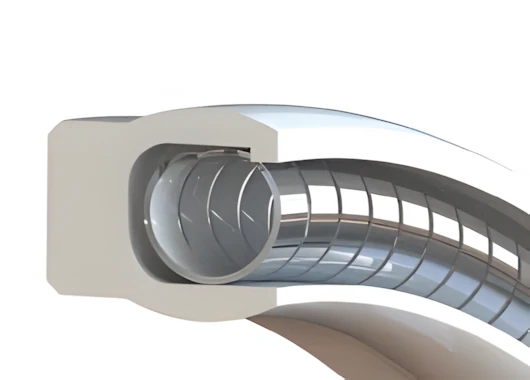

This is the domain of the Spring Energized Seals (SES), a component born from the necessity to overcome the inherent limitations of traditional sealing materials. The spring energized seals are not merely a more robust version of a standard seal; it is a fundamentally different technology based on a polymer jacket and metal spring design. This combination provides a high degree of reliability and resilience, forming one of the most effective high-performance sealing solutions in the field. It masterfully combines the desirable properties of two dissimilar materials: a high-performance polymer jacket and a metallic spring energizer.

This synergy creates a seal that possesses the near-universal chemical inertness and wide temperature range of an advanced polymer, coupled with the persistent, resilient sealing force of a metal spring. It is the quintessential “problem-solver” in mechanical engineering seals, engineered to provide reliability and integrity where other seals cannot survive. This definitive sealing technology guide will explore the intricate world of spring energized seals, deconstructing their polymer jacket and metal spring design, analyzing their constituent materials, examining the spectrum of industrial sealing applications, and outlining the rigorous engineering principles required for their successful implementation. For engineers facing the most demanding sealing challenges, the SES represents the apex of performance and a key enabler of technological advancement.

The Fundamental Principle: Overcoming the Limitations of Material Science

To fully appreciate the genius of spring energized seals, one must first understand the fundamental trade-offs in sealing material properties. Sealing materials can be broadly placed on a spectrum defined by elasticity and performance range.

- Elastomers (Rubbers): Materials like NBR and FKM possess excellent elasticity and “memory.” When compressed, they store energy and exert a strong “push-back” force, which is ideal for sealing. However, their operational window is limited. At high temperatures, they degrade and take a permanent compression set. At cryogenic temperatures, they become brittle and glass-like. Their chemical compatibility, while good for specific families (like FKM for hydrocarbons), is not universal. For this reason, elastomer alternatives such as SES are often necessary in extreme applications.

- High-Performance Polymers (Fluoropolymers): Materials like Polytetrafluoroethylene (PTFE) sit at the opposite end of the spectrum. PTFE offers a phenomenal performance range: it is virtually inert to all chemicals, has an extremely low coefficient of friction, and maintains its properties from deep cryogenic temperatures to over 260°C (500°F). However, PTFE is a thermoplastic, not an elastomer. It has very poor memory and is highly susceptible to “creep” or cold flow under load. A seal made from solid PTFE would provide an initial seal but would quickly lose its sealing force and leak, especially under low pressure or in applications with thermal cycling.

The spring energized seals were invented to resolve this paradox. It leverages the strengths of both material types while mitigating their weaknesses. The PTFE (or other polymer) jacket provides the seal’s interface with the hardware and the media, delivering the required thermal, chemical, and frictional performance. The metal spring, housed within the jacket, acts as the “engine,” providing the permanent, resilient mechanical energy that the polymer lacks. It constantly pushes the lips of the jacket outwards, ensuring a continuous, positive sealing force against the hardware surfaces, regardless of system pressure, temperature fluctuations, or material creep. This polymer jacket and metal spring design is the key to its extraordinary versatility and reliability, especially in cryogenic and high-temperature seals.

Deconstructing the Spring Energized Seal: An Anatomical Study

A spring energized seal is a precision assembly of two core components: the polymer jacket and the spring energizer. The design and material selection of each part are tailored to the specific demands of the application, making it one of the most reliable spring energized seals solutions in modern industrial sealing applications.

1. The Polymer Jacket: The Sealing Barrier

The jacket is the body of the spring energized seals. It is machined from a tube of high-performance polymer into a specific profile (often a U-cup or C-profile) with one or more sealing lips. Its primary functions are to provide the chemical and thermal barrier, and to create the low-friction dynamic or static sealing surface.

Jacket Materials:

- PTFE and its Compounds: This is by far the most common jacket material. Virgin PTFE is used where low friction is paramount. However, to enhance its mechanical properties, PTFE is most often blended with fillers. Common fillers include:

- Carbon/Graphite: Improves wear resistance, thermal conductivity, and compressive strength. A very common choice for dynamic applications.

- Glass Fiber: Significantly increases wear resistance but can be abrasive to softer hardware.

- Bronze: Offers the best wear resistance and creep resistance but has limited chemical compatibility.

- Polymer Fillers: Blending with materials like PEEK or Ekonol® can dramatically improve creep and wear resistance.

- PEEK (Polyether Ether Ketone): For applications requiring extreme strength, hardness, and extrusion resistance at very high temperatures, PEEK is an excellent, albeit more costly, jacket material. It is often the choice for backup rings in high-pressure Piston Seals or as the primary material in demanding Compressor Spare Parts.

- UHMW-PE (Ultra-High-Molecular-Weight Polyethylene): Known for its exceptional abrasion resistance in slurry or particulate-laden media, though with a more limited temperature range than PTFE.

The jacket’s lip design is also critical. It can be a sharp “knife-edge” for cutting through viscous media, a beveled edge for standard dynamic sealing, or a flat face for static applications.

2. The Spring Energizer: The Engine of the Spring Energized Seals

The spring is the heart of the SES. It provides the initial seating load for sealing at low pressures and compensates for wear, creep, and thermal expansion and contraction of the jacket. The choice of spring type and material determines the seal’s load characteristics and its suitability for different applications.

Common Spring Types:

- V-Spring (Cantilever Spring or Meander Spring): This is the most common and versatile spring type. It is a stamped, folded ribbon of metal that provides a moderate to high load with a relatively steep load-deflection curve. It offers an excellent balance of properties and is highly effective in reciprocating rod and piston seals, as well as static face seals.

- Helical Spring: A helically wound ribbon of wire, this spring provides a very high load. It is ideal for sealing in applications with highly viscous media, imperfect hardware surfaces, or where very low leakage is required. Its high load, however, translates to higher friction, making it more suitable for static or slow-speed dynamic applications. A common material is high-strength Helical Spring SS301.

- Canted Coil Spring: This is a specialty spring where the coils are canted at an angle. It provides a very consistent load over a wide range of deflection. This makes it ideal for applications with significant hardware tolerances, large thermal expansion, or where a constant frictional force is desired.

Spring Materials: The spring material must have excellent corrosion resistance and maintain its mechanical properties at the service temperature. Common choices include 300-series Stainless Steel for standard applications, and high-nickel alloys like Elgiloy® or Inconel® for highly corrosive or high-temperature environments.

A Spectrum of Applications: Where Spring Energized Seals Excel

The unique combination of a high-performance jacket and resilient metal spring allows SES to thrive in challenging industrial sealing applications:

- Cryogenic Service: In LNG pumps, cryogenic valves, and aerospace fuel systems, temperatures can plummet below -150°C (-238°F). Elastomers become brittle, but the PTFE jacket and metal spring of an SES retain their functional properties, providing a reliable seal.

- High-Temperature Service: In gas turbines, hot gas valves, and downhole oil and gas equipment, temperatures can exceed 250°C (482°F). The SES, with a suitable polymer jacket (like filled PTFE or PEEK) and a high-nickel alloy spring, can maintain its integrity and sealing force.

- High-Pressure and High-Speed Dynamic Systems: In high-pressure pumps and compressors, the low-friction properties of the PTFE jacket reduce heat generation, while the spring ensures a consistent lip contact. This allows for higher pressures and speeds than are possible with traditional elastomeric lip seals. They are also used as heavy-duty Rod Seals in hydraulic systems with aggressive fluids.

- Aggressive Chemical Media: For sealing in chemical reactors, pumps, and valves handling acids, solvents, and other corrosive substances, the near-universal chemical inertness of the PTFE jacket provides a level of safety and reliability that no elastomer can match.

- Vacuum and Ultra-Clean Environments: In semiconductor manufacturing, medical equipment, and laboratory instruments, outgassing from seal materials can contaminate sensitive processes. Specially cleaned and formulated SES have very low outgassing properties. The spring provides a positive sealing force even in a vacuum where there is no pressure to energize the seal.

- Food, Beverage, and Pharmaceutical: SES made from FDA-compliant materials are ideal for sanitary applications. They have no voids or crevices where bacteria can be trapped, and they can withstand aggressive clean-in-place (CIP) and sterilize-in-place (SIP) procedures.

Critical Design and Implementation Parameters for Success

The high-performance nature of a spring energized seal is matched by its need for precision in the surrounding hardware and installation. A successful outcome depends on a systems approach to design.

1. Gland Design: The Foundation for Performance

The groove or gland where the seal sits is not just a housing; it is an integral part of the sealing system.

- Surface Finish: This is arguably the most critical hardware parameter, especially for dynamic seals. The dynamic surface (rod or bore) must be very smooth (typically 0.1 to 0.4 µm Ra / 4 to 16 µin Ra) to prevent abrading the relatively soft PTFE jacket. The finish on the static groove surfaces is less critical but should be free of burrs and sharp edges.

- Hardware Hardness: To prevent wear from the filled PTFE compounds, the dynamic hardware surface should ideally be hardened to 55 HRC or greater.

- Lead-In Chamfers: Sharp corners on the hardware can easily cut or damage the jacket during installation. Generous, radiused lead-in chamfers are mandatory for guiding the seal into its groove safely.

- Gland Dimensions and Tolerances: The gland diameter and width must be precisely machined to ensure the correct fit and to support the seal against deflection under pressure.

2. Seal Configuration: Tailoring the Design to the Task

Spring energized seals are not one-size-fits-all. The profile of the jacket is engineered for specific functions.

- Rod Seals (External Sealing): The lips are designed to seal on the internal diameter. The heel of the seal is often squared off to provide stability in the groove.

- Piston Seals (Internal Sealing): The lips are designed to seal on the outer diameter.

- Static Face Seals (Axial Sealing): The lips are designed to seal on the flat face of a flange or housing. The spring load is directed axially.

- Lip Design: The sealing lips can be designed for specific purposes—a scraper lip can be added to exclude media, while a relieved lip can reduce running friction.

3. Installation: The Final, Crucial Step

Improper installation is a primary cause of premature failure for spring energized seals. Because the PTFE jacket is not as forgiving as an elastomer, extra care is required.

- Use of Specialized Tools: Two-piece installation tools or resizing tools are often required, especially for small-diameter seals, to avoid over-stretching or damaging the jacket.

- Cleanliness: The seal and the hardware must be meticulously clean before assembly.

- Protection from Sharp Edges: If the seal must pass over threads or ports, a protective sleeve must be used.

- No Lubrication Required (Usually): Unlike elastomeric seals, PTFE seals are self-lubricating and should typically be installed dry, unless a compatible fluid is used to aid assembly.

Conclusion: The Synthesis of Material and Mechanics for Ultimate Reliability

The spring energized seals stand as a remarkable achievement in sealing technology. It is a testament to how the clever synthesis of material science and mechanical engineering can overcome the limitations of individual materials to create a whole that is far greater than the sum of its parts. It is not just a seal; it is an engineered solution, custom-designed to provide a robust and reliable barrier in applications where failure is not an option. From the vacuum of space to the depths of an oil well, from cryogenic liquids to superheated steam, the SES provides the enabling technology that allows for safer, more efficient, and more advanced industrial processes.

The journey to a successful implementation, however, is one of precision. It demands a thorough understanding of the application, a careful selection of jacket and spring materials, and an unwavering commitment to a high-quality hardware finish and meticulous installation practices. By embracing this engineered approach, we can harness the full potential of these exceptional seals to solve the most formidable sealing challenges imaginable.