Introduction: The Material as the Message

In the intricate design of any fluid handling system, the sealing ring materials selected for production play a determining role in long-term system reliability. In the engineering world, the sealing ring stands as a component of fundamental importance. Its geometry, profile, and the precision of its gland are all critical engineering considerations. Yet, these factors are ultimately secondary to the single most decisive element that dictates its success or failure: the material from which it is made. In sealing technology, choosing the right sealing ring materials becomes the decisive foundation of performance.

The sealing ring materials are the essence of sealing — the cornerstone upon which its sealing performance is built. It must withstand the chemical attack of the media, tolerate thermal extremes, and possess the mechanical resilience required to maintain sealing force under pressure and motion. An impeccably designed ring made from an inappropriate material is not simply a flawed component; it becomes a guaranteed point of failure.

This reality elevates material science from a supporting role to the central pillar of sealing technology. A superficial understanding of generic trade names is no longer enough. Engineers must understand chemical compatibility, mechanical properties of sealing materials, thermal limits, and material behavior under load and deformation.

Why is FKM the choice for high-temperature fuel, while EPDM is the standard for automotive brake fluid? What makes filled PTFE superior to elastomers for high-speed rotary motion? When does the application demand the unyielding strength of a metal alloy? This guide is dedicated to answering these questions. We will embark on a deep dive into the world of Sealing Materials, providing a comprehensive analysis of the major material families, their key properties, and the systematic process required for their selection. This exploration is foundational to transforming a sealing ring from a simple component into a high-reliability engineering solution.

The Framework for Evaluation: Key Properties of Sealing Ring Materials

Before comparing specific materials, it is crucial to establish a consistent framework of the properties by which they are judged. The performance of a sealing ring is a multi-faceted balance of these characteristics. A material that excels in one area may be deficient in another, and the art of selection lies in finding the optimal compromise for a given application. This is why sealing ring materials must be evaluated holistically.

- Chemical Compatibility: This is the paramount consideration. The material must be able to resist degradation when exposed to the system fluid, as well as any cleaning agents or environmental factors. Chemical attack can manifest as swelling, softening, hardening, cracking, or complete dissolution of the ring.

- Temperature Range: Every material has a specific service temperature window. The high-temperature limit is where the material begins to lose its mechanical properties or degrade through heat aging. The low-temperature limit (often the Glass Transition Temperature, Tg) is where it loses its flexibility and ability to seal, becoming hard and brittle.

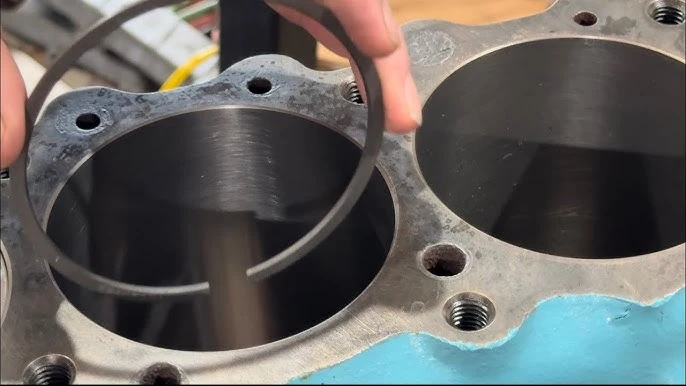

- Hardness (Durometer): This is a measure of a material’s resistance to indentation. For elastomers, it is typically measured on the Shore A scale. Harder materials offer greater resistance to extrusion and wear but are less conformable to surface imperfections. Softer materials seal with lower clamping forces but are more prone to damage.

- Tensile Strength and Elongation: Tensile strength is the material’s ability to resist being pulled apart. Elongation-at-break measures how much it can stretch before failing. These properties are key indicators of a material’s toughness and resistance to installation damage.

- Compression Set Resistance: This is a critical measure of a sealing ring’s long-term performance. It quantifies a material’s ability to return to its original shape after being held in a compressed state. A material with a high compression set (poor resistance) will become flat over time, losing its “push-back” force and leading to leaks.

- Abrasion and Wear Resistance: In dynamic sealing ring applications (reciprocating or rotary), this property is vital. It describes the material’s ability to withstand the frictional wear from rubbing against a moving hardware surface.

- Pressure Rating and Extrusion Resistance: This is the material’s ability to resist being physically forced into the clearance gap between hardware components under high pressure. It is directly related to material hardness and modulus.

Evaluating a potential sealing ring materials require a thorough analysis of its performance across this entire spectrum of properties in the context of the specific application’s demands.

The Elastomer Family: Sealing Through Resilience

Elastomers are the most common materials for sealing rings, particularly for the ubiquitous O-Rings. Their defining characteristic is their high elasticity, which allows them to be squeezed into a gland and maintain a constant, live sealing force.

Nitrile (NBR) — The Workhorse of Elastomers for Sealing

Nitrile Butadiene Rubber is the workhorse of the sealing industry. It is a copolymer of acrylonitrile (ACN) and butadiene. The ACN content (typically 18% to 50%) determines its key properties.

- Key Strengths: Its primary advantage is excellent resistance to petroleum-based fluids, such as mineral oils, hydraulic fluids, and hydrocarbon fuels. It also has very good mechanical properties, including high abrasion resistance and tensile strength. Crucially, it is the most cost-effective sealing elastomer.

- Limitations: Its primary weaknesses are a relatively modest high-temperature limit (around 100°C to 125°C) and poor resistance to weathering, sunlight (ozone), and polar fluids like ketones, esters, and brake fluids.

- Typical Applications: Standard hydraulic and pneumatic systems, automotive fuel and oil handling, general-purpose industrial applications.

This makes NBR a cornerstone material in NBR sealing technology.

Fluorocarbon (FKM) — High-Temperature Sealing Solutions

Commonly known by its DuPont trade name Viton™, FKM is a family of fluoroelastomers that represents a significant step up in performance from NBR.

- Key Strengths: FKM is renowned for its exceptional high-temperature resistance (continuously up to 200°C / 400°F) and its broad chemical compatibility. It resists petroleum oils, synthetic lubricants, many solvents, and acids. It also has excellent resistance to aging, weathering, and ozone.

- Limitations: Its low-temperature flexibility is generally not as good as NBR’s. It is also not suitable for use with polar solvents, ketones (like acetone), or certain organic acids. Its cost is substantially higher than NBR.

- Typical Applications: High-temperature automotive and aerospace systems, chemical processing, high-vacuum applications, and any general industrial application where the temperature or chemical environment exceeds the capabilities of NBR.

EPDM — Polar Fluid & Weather-Resistant Performance

EPDM is an elastomer known for its unique chemical compatibility profile, which is almost the inverse of NBR.

- Key Strengths: EPDM’s primary strength is its outstanding resistance to polar fluids. This includes hot water, steam, automotive brake fluids (glycol-based), ketones, and some acids. It also has excellent resistance to weathering, sunlight, and ozone, making it ideal for outdoor applications.

- Limitations: Its fatal flaw is its complete lack of resistance to petroleum-based fluids (oils, gasoline, solvents). Exposure to these will cause the material to swell excessively and degrade.

- Typical Applications: Automotive cooling and braking systems, water and steam valves, outdoor hydraulic systems using water-based fluids, food and beverage applications (using peroxide-cured grades). These characteristics make EPDM rubber applications critical in automotive and industrial sectors.

Silicone (VMQ) — Extreme Temperature Elasticity

Silicone rubber is a specialist material prized for its enormous service temperature range.

- Key Strengths: Silicone’s standout feature is its thermal stability. It can function from as low as -60°C up to 225°C (-75°F to 437°F). It is also physiologically inert, making it suitable for sanitary applications, and has good resistance to weathering and ozone.

- Limitations: Its mechanical properties are generally poor. It has low tensile strength and very poor abrasion and tear resistance, which typically makes it unsuitable for dynamic sealing rings. It also has limited chemical compatibility, particularly with hydrocarbon fuels and oils.

- Typical Applications: Primarily static sealing rings in extreme temperature applications, such as oven door seals, and in food, medical, and pharmaceutical applications where cleanliness and inertness are required.

The Polymer Family: Sealing Through Strength and Low Friction

This family includes more rigid materials that offer performance characteristics, particularly in mechanical strength and friction, that elastomers cannot match. They are the core materials for engineered hydraulic and pneumatic sealing rings.

Polytetrafluoroethylene (PTFE) — Universal Chemical Resistance

PTFE is a fluoropolymer with a unique and highly desirable combination of properties, making it one of the most important sealing materials for challenging applications.

- Key Strengths: PTFE’s claim to fame is its near-universal chemical inertness; it is resistant to almost all industrial chemicals. It has an extremely low coefficient of friction (the lowest of any solid material) and a very wide service temperature range.

- Limitations: Virgin PTFE is a soft material that exhibits creep (cold flow) under load and has poor wear resistance. To overcome this, PTFE is almost always blended with fillers (carbon, glass, bronze, etc.) to create compounds with vastly improved mechanical properties. It also has no elasticity, so it must be energized by system pressure or a spring.

- Typical Applications: As the jacket material for Spring Energized Seals; as the primary sealing ring in Glyd Ring style Piston Seals; high-performance PTFE sealing rings for high-speed rotary applications; and chemically resistant PTFE Gaskets.

Polyurethane (PU) — The Toughest Dynamic Sealing Material

Polyurethane is a thermoplastic elastomer that bridges the gap between rubbers and plastics.

- Key Strengths: PU’s defining characteristic is its exceptional mechanical toughness. It has outstanding abrasion resistance, high tear strength, and excellent extrusion resistance. This makes it incredibly durable in dynamic applications.

- Limitations: Its primary weakness is its susceptibility to hydrolysis; it can degrade in hot water or humid environments. Its high-temperature limit is also modest compared to FKM or PTFE.

- Typical Applications: The undisputed material of choice for demanding hydraulic sealing rings, particularly dynamic Rod Seals and Wiper Seals, where its toughness provides a long, reliable service life.

Polyether Ether Ketone (PEEK) — High-Strength Polymer for Extreme Conditions

PEEK is a high-performance, semi-crystalline thermoplastic at the top tier of the polymer pyramid.

- Key Strengths: PEEK possesses an extraordinary combination of high strength, stiffness, and hardness, which it retains at very high temperatures (up to 260°C / 500°F). It has excellent fatigue and creep resistance and good chemical compatibility.

- Limitations: It is a very hard, rigid material with low elasticity, so it is not used for primary sealing in the same way as softer materials. It is also one of the most expensive polymers.

- Typical Applications: As a structural component that also seals, such as PEEK Valve Plates in compressors; as high-performance backup rings to prevent extrusion of other seals in ultra-high-pressure systems; and as wear rings and bushings. Victrex | Innovative world leader in high performance PEEK polymers

The Metallic Family: Sealing Through Unyielding Strength

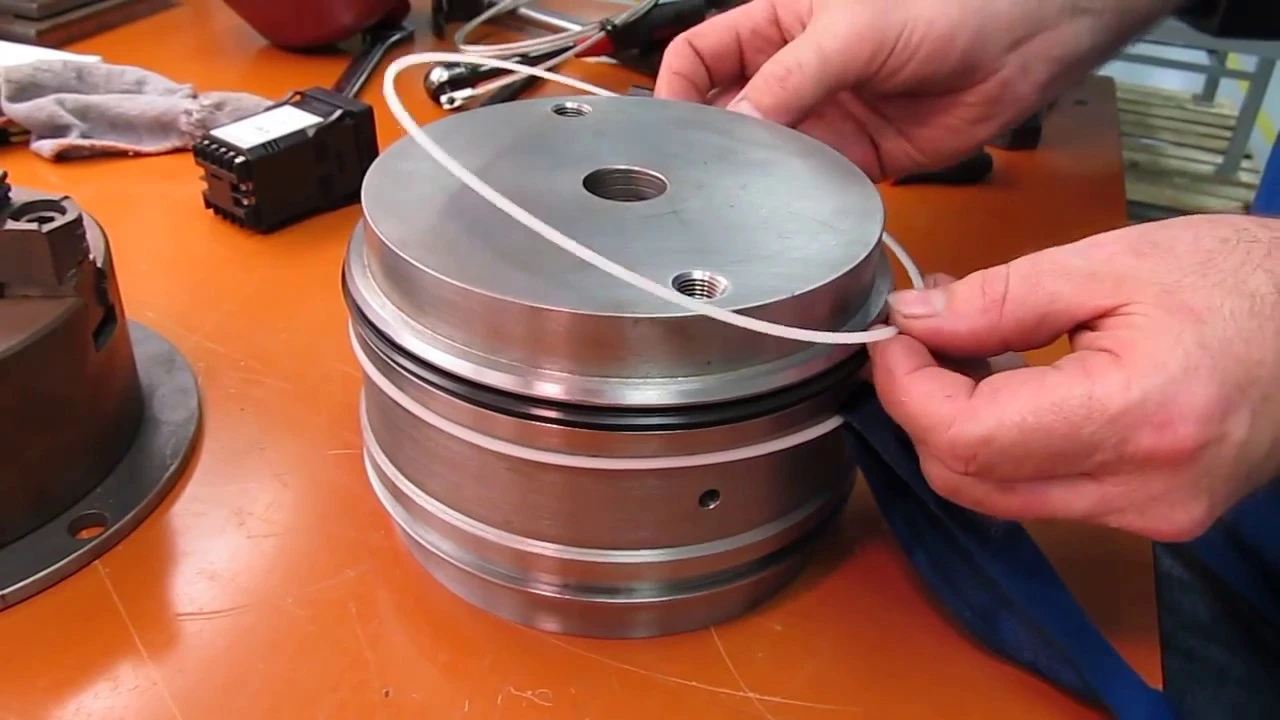

For applications where temperatures, pressures, or radiation levels are so extreme that they would destroy any polymer, metallic sealing rings are the only solution. They seal through the high-stress plastic or elastic deformation of metal.

Stainless Steels (300 Series)

Austenitic stainless steels are the most common choice for metallic sealing ring materials due to their good corrosion resistance and formability.

- Key Strengths: Excellent general corrosion resistance, good strength, and good performance at both moderately elevated and cryogenic temperatures.

- Typical Applications: As the structural case for Oil Seals; as the energizing spring (e.g., SS301) in spring energized seals; and as the parent material for some all-metal sealing rings.

High-Nickel Alloys (Inconel®, Hastelloy®)

These “superalloys” are used when conditions exceed the capabilities of stainless steel.

- Key Strengths: They maintain extremely high strength at very high temperatures and are resistant to a wide range of highly corrosive media, including sour gas and strong acids.

- Typical Applications: The definitive choice for the most demanding Metal Sealing Rings, such as Hollow Metal O-Rings used in gas turbines, nuclear reactors, and extreme downhole oil and gas equipment.

The Synthesis: A Systematic Process for Sealing Ring Materials Selection

With such a vast palette of sealing ring materials, a structured selection process is essential to avoid costly errors.

- Step 1: Identify Chemical Media and Temperature Range. This is the first and most critical filter. Create a list of all fluids and chemicals the sealing ring will encounter. Determine the minimum and maximum operating temperatures. Use chemical compatibility charts to create a shortlist of material families that can survive in this environment (e.g., FKM, EPDM, PTFE, PEEK, Metal).

- Step 2: Define the Application and Pressure. Is the ring static or dynamic? What is the maximum system pressure? For a high-pressure dynamic application, you will be guided towards tough, extrusion-resistant materials like PU or engineered solutions like PEEK backup rings. For a static application, a wider range of materials may be suitable.

- Step 3: Evaluate Mechanical Demands. If the application is dynamic, consider the need for low friction (points to PTFE) or high abrasion resistance (points to PU). For all applications, consider the hardware’s surface finish; a conformable elastomer can handle a rougher surface than a rigid metal ring. Evaluate the need for long-term sealing force, which prioritizes sealing ring materials with excellent compression set resistance.

- Step 4: Consider Cost and Availability. With a final shortlist of technically suitable materials, the decision can be refined based on cost. An FFKM ring may be technically superior, but if a standard FKM ring can perform the job reliably, it will be the more economical choice.

Conclusion: The Material is the Message

The performance, reliability, and safety of a system are inextricably linked to the sealing ring materials chosen for its sealing rings. The vast array of available materials is not a source of confusion but a testament to the specialized solutions that have been developed to meet the ever-increasing demands of modern industry. From the versatile resilience of NBR to the unyielding strength of a nickel superalloy, each material tells a story of its intended purpose and operational boundaries.

A successful sealing ring is therefore not merely a product of good geometry, but the result of a deliberate and informed material selection process. It requires a deep understanding of the application’s environment and a corresponding knowledge of how different materials will behave within it. By approaching material selection with this systematic, property-driven mindset, engineers can ensure that the sealing rings they specify are not just components, but true cornerstones of system performance and integrity.