In the hierarchy of sealing technology, there is a distinct “line in the sand.” On one side, you have elastomers like NBR and FFKM, which handle the vast majority of industrial applications. On the other side, you have environments so hostile—be it -270°C cryogenics or extreme radiation—that polymer chains simply disintegrate. This is where the metal C ring becomes the only viable option.

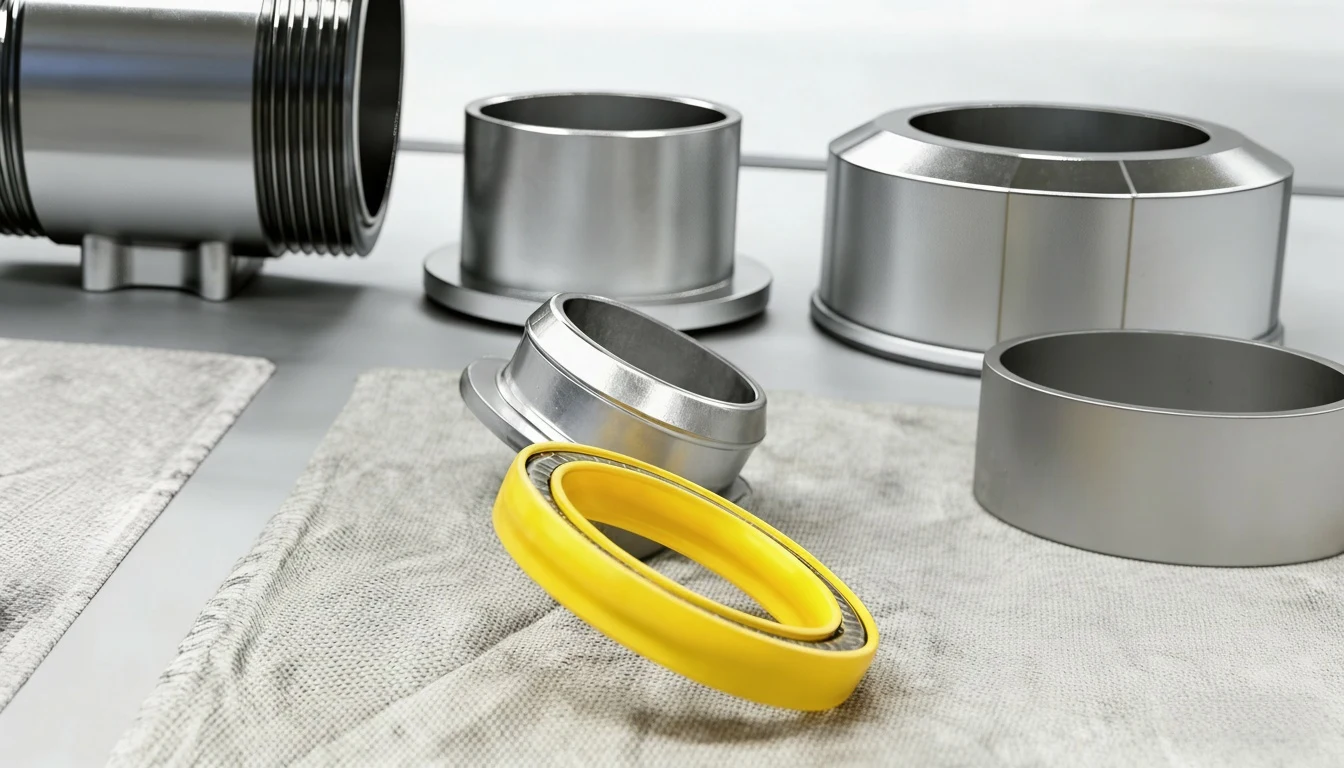

At QZSEALS, we engineer these metallic seals for clients who have pushed standard materials to their breaking point. Unlike a solid metal washer, a Metal C-Ring is designed with a specific elasticity, allowing it to function as a spring. This guide explores why and how we deploy this specialized component.

The Physics of the “C” Profile

The defining characteristic of a metal C ring is its open cross-section. Imagine a metal tube cut in half. When installed in a groove and compressed, the open “C” shape compresses, generating a spring-back force against the mating surfaces.

Why choose a “C” profile over a standard Metal O-Ring? It comes down to load and resilience:

- Lower Sealing Load: C-rings require significantly less compressive force to seal than solid or hollow metal O-rings. This makes them ideal for lighter flanges or delicate hardware.

- High Springback: The open geometry allows for greater elastic recovery (springback). This is critical in applications with thermal cycling, where the flange expands and contracts.

The “Self-Energizing” Effect

One of the most brilliant engineering features of the metal C ring is its ability to use system pressure to its advantage. As a type of self-energizing static seal, the metal C ring must be installed with the open side of the “C” facing the pressure source.

As the internal pressure of the system rises, it enters the cavity of the C-ring and pushes the walls outward against the sealing surfaces. This means the higher the pressure, the tighter the seal becomes. This self-energizing capability is why they are a staple in high-pressure aerospace valves and nuclear reactor cooling lines.

You can view our specific specifications here: Metal C-Rings.

Material Selection: Beyond Steel

Manufacturing a metal C ring is not just about shaping steel. It involves selecting superalloys that retain strength at extreme temperatures. At QZSEALS, we typically utilize:

- Inconel 718 / X-750: The industry standard materials for Inconel C-rings, offering exceptional high-temperature strength, oxidation resistance, and fatigue performance in aerospace, energy, and vacuum systems.

- Stainless Steel (304/316): Used for less aggressive cryogenic sealing applications, offering reliable performance at low temperatures in accordance with ASTM material standards, which with lower material cost compared to nickel-based superalloys.

The Importance of Plating

Metal-to-metal sealing is difficult because metal does not “flow” into surface imperfections like rubber does. To solve this, we often plate our metal C ring with softer metals like silver, gold, or PTFE. Under compression, this soft plating flows into the microscopic scratches of the flange, creating a gas-tight seal essential for Ultra-High Vacuum sealing applications.

Comparison: Metal C-Ring vs. Other Metal Seals

Choosing the right metal seal is critical. Here is how the C-ring stacks up against its counterparts in our catalog:

- vs. Metal O-Rings: Metal O-Rings (hollow or gas-filled) are more robust and handle higher pressures but require much higher clamping force. If your bolts cannot handle the load, switch to a C-Ring.

- vs. Hollow Metal O-Rings: Hollow Metal O-Rings are excellent, but the C-ring offers better “springback” to compensate for flange separation during thermal shock.

Installation Criticalities

From our manufacturing experience, the number one cause of metal C ring failure is surface finish. Unlike a Rubber Ring that can seal against a rough surface, a metal seal requires a polished finish (typically 0.4 to 0.8 Ra depending on the plating). Handling is also critical; a single scratch across the seal face during installation will create a leak path that cannot be fixed by tightening the bolts.

Conclusion

The metal C ring is an elite component for elite applications. Whether you are sealing liquid nitrogen or high-pressure steam, understanding the relationship between the “C” profile orientation and the system pressure is key to success.

At QZSEALS, we provide the technical support needed to transition from failing elastomer seals to permanent metal sealing solutions. For specialized designs, including varying wall thicknesses and plating options, explore our Metal Sealing Rings Category.