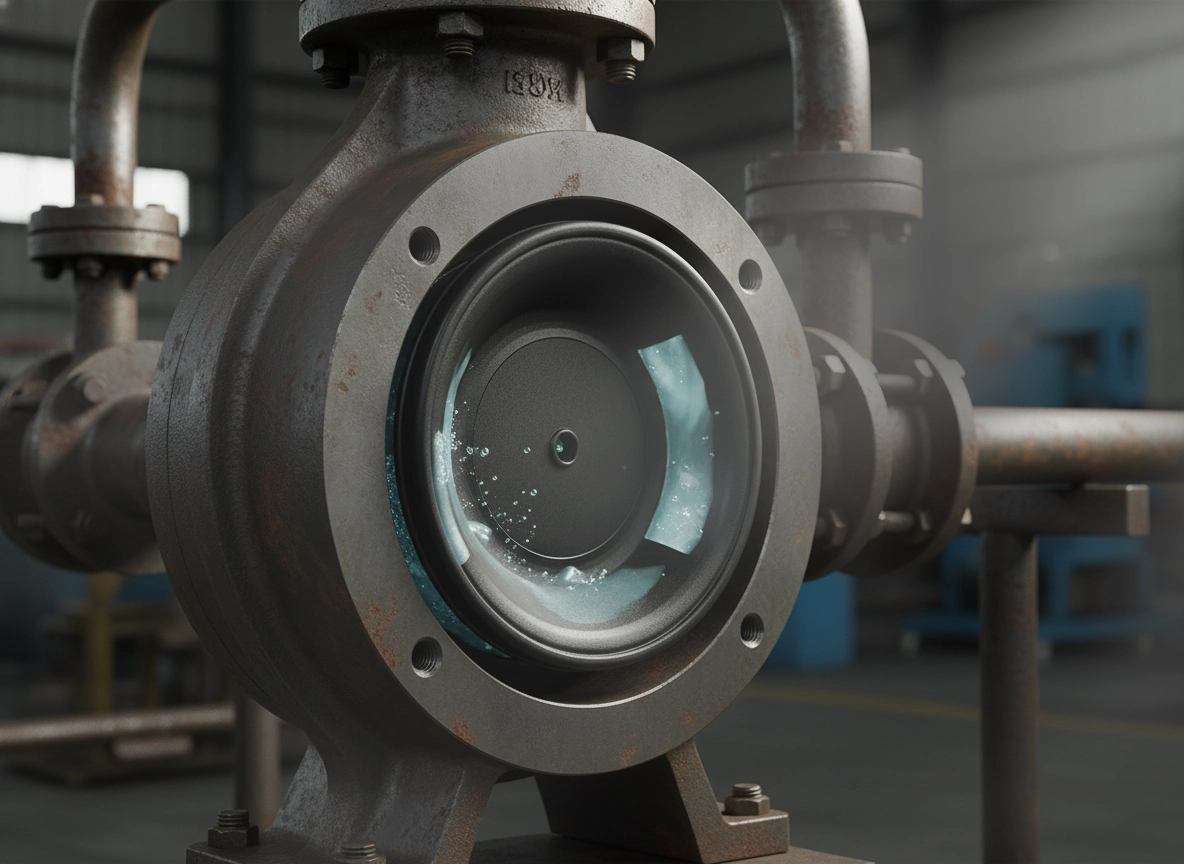

Hydraulic seals are the backbone of reliable industrial machinery. In the global industrial market, a great design is only the starting point. For Original Equipment Manufacturers (OEMs) and large-scale maintenance operations, the true value of a sealing partner lies in consistency. A hydraulic seal delivered to a factory in Germany must be identical to one delivered to a mine in Australia. Quality cannot fluctuate, and consistent sealing solutions are essential for maintaining uptime and safety.

QZSEALS has built its reputation not just on engineering innovation, but on manufacturing excellence. We combine advanced molding technology with rigorous testing protocols to ensure that every O-ring and piston seal meets the highest international standards. Our focus on hydraulic seals ensures that each component performs reliably under demanding operating conditions.

This article takes you behind the scenes. We will explore the manufacturing processes of types of seals, from mass-produced rubber parts to precision-machined PTFE, and detail the strict quality control measures that define the QZSEALS brand. We also highlight how our global supply chain guarantees timely delivery across continents.

Part 1: The Manufacturing Spectrum

Sealing production is not a “one-size-fits-all” process. QZSEALS employs diverse manufacturing methods to provide tailored sealing solutions for different volumes and materials, including specialized hydraulic seals for industrial and mobile applications.

Precision Rubber Molding

For high-volume items like the TC Oil Seal or standard O-Ring Rubber Seals, compression and injection molding are key.

- Consistency: Automated molds ensure that millions of parts have identical tolerances.

- Material Control: We strictly control the raw gum mix—whether NBR, FKM, or Silicone—to ensure the cured seal meets specific hardness and tensile strength requirements.

- Custom Shapes: Our Customized Rubber Products service allows for the creation of complex geometries, such as boots, bellows, and irregular gaskets.

CNC Machining and Turning

For high-performance engineering plastics, we utilize advanced CNC technology.

- PTFE Processing: Seals like the PTFE Oil Seal with Stainless Steel case are precision-assembled. The PTFE lip is machined to a razor-sharp tolerance to ensure a perfect seal on high-speed shafts.

- Guide Rings: PTFE Filled Bronze Guide Tape is skived to exact thicknesses. Precision cutting ensures that the scarf joints match perfectly during installation.

Vulcanization and Splicing

For large-diameter static sealing where a single mold is too expensive, we employ hot vulcanization.

Using O-Ring Cords, we create rings of unlimited diameter. The splice joint is tested to ensure it is as strong as the cord itself.

Part 2: Quality Control Protocols

A seal is a safety-critical component. QZSEALS implements a multi-stage Quality Assurance (QA) process.

Raw Material Testing

Before production begins, the material is tested.

- Elastomers: We test for specific gravity, hardness (Shore A), and elongation. A Custom Inflatable Seal relies on precise elasticity; if the rubber is too stiff, it will not inflate; too soft, and it will burst.

- Springs: For Spring Energized Seals, the metal springs (Stainless Steel 301 Helicoil Springs) are tested for load force consistency.

In-Process Inspection

During manufacturing, operators perform visual and dimensional checks.

For complex assemblies like the SPGW Piston Seal, we ensure the back-up rings fit perfectly with the PTFE face. Any deviation results in immediate rejection.

Final Audit and Batch Testing

Before shipment, random samples undergo rigorous stress tests.

- Leak Testing: Specialized rigs test Gear Pump Seals under pressure.

- Surface Finish: PEEK Valve Plates are inspected for flatness. A warped plate causes compressor inefficiency.

Part 3: The Customization Workflow

How do we move from a customer’s sketch to a finished product? The QZSEALS engineering team follows a structured path.

Step 1: Consultation and Design

We analyze the application parameters. If a customer needs a seal for a sanitary pump, we might suggest a Fabric Reinforced Rubber Diaphragm.

Step 2: Prototyping

We produce samples fast. For non-standard housing, we might machine a prototype Custom L2M Oil Seal. This allows the customer to test fit and function without committing to expensive tooling.

For engineers seeking global benchmarks in hydraulic seals and leakage control, it’s important to follow recognized industry standards. Authoritative specifications and testing protocols for sealing components and related materials are available from the International Organization for Standardization. Explore comprehensive guidelines at ISO Standards.

Step 3: Mass Production

Once approved, we scale up. Whether it is 100 units of Hollow Metal O-Rings or 10,000 units of A5 Wiper Seals, our supply chain ensures timely delivery.

Part 4: Global Logistics and Supply Chain

QZSEALS serves customers across multiple countries. Logistics is a key part of our service offering.

Kitting and Packaging

OEMs often require complete repair kits rather than loose parts. We provide:

- Cylinder Kits: Bundling a SPG Piston Seal, IDI Rod Seal, and PDR Wiper Seal into a single, labeled package for easy aftermarket sales.

- Protection: Delicate items like PTFE Gaskets are packaged with rigid backing to prevent bending during transit.

Inventory Management

We maintain stock of critical items. High-demand products like FEP Encapsulated O-Rings and GSJ Seal Step Seals are kept ready for rapid dispatch to minimize client downtime.

Part 5: Innovation and Future-Proofing

Manufacturing does not stand still. QZSEALS invests in the future.

Advanced Materials

We are constantly testing new compounds. From improving the wear life of Phenolic Resin with Fabric Wear Rings to developing lower-friction PTFE blends for Glyd Rings, innovation drives us.

Sustainable Practices

Efficiency reduces waste. Our precision molding techniques reduce “flash” (waste rubber), and our durable materials like Aramid Fiber Gland Packing ensure seals last longer, reducing the frequency of disposal.

Conclusion: Your Trusted Industrial Partner

In the end, hydraulic seals is promise of performance. When you install a QZSEALS component, you are trusting us with the integrity of your machine.

Through strict quality control, advanced manufacturing, and a responsive global supply chain, we honor that trust. Whether you need a standard Compact Seal S8 or a bespoke engineering project, QZSEALS is equipped to deliver.

Explore our full capabilities in Rod Seals, Piston Seals, and Wiper Seals. Partner with QZSEALS for reliability that spans the globe.